Simatec is all about beer, housing both a brewery equipment manufacturing division and a microbrewery in Italy. This diverse knowledge base under one roof is handy and has led the manufacturing side to develop some innovative technical solutions based on the operating needs of the brewery side.

We will get to the overall specs of the Simatec system below, but the headline here is the multifunctional capabilities and modular build of the Simatec brewhouse, which, in addition to general operational efficiency, is constructed with production expansion in mind. Simatec says its Multi-Brew tanks increase production cycles without needing to modify the existing system, just by adding another component, as you might in the fermenting cellar, and will only require a two-day stoppage in production.

How does it all come together? Time to dive into the specs.

And remember to read the first in our efficient brewhouse series: The HEBS

Heating element

Steam is usually the heating element of choice for today’s brewer because it’s easy to produce, cheap to control thanks to its low density and can circulate in the heating jackets at high speed, enabling work at low temperatures.

All Simatec brewhouses use saturated steam at variable pressure, produced at a pressure of 5 bar of atmospheric pressure (about 160 degrees C) and can be adjusted in a range between 1 and 5 bar, at a temp of about 115 C and 160 C. The high speed that the steam reaches in the jackets with a turbulent movement allows a high exchange also at the lowest temperatures.

Simatec says the advantage is to have well controlled and fast heating when needed (not functional heating), with a really gentle action on the wort that enables production of a really clear and fresh pilsner, or, for a really cooked and caramelized wort, increasing the steam pressure (its temperature) to produce a Belgian or barley wine.

The Multi-Brew multifunctinal tank of the Simatec brewhouse has the following heating elements:

• Jacket on the conical bottom that can increase the wort convective circulation.

• Heating jacket on the plating that can increase the wort convective turbulence.

The heating jackets on the bottom and on the cylindrical part have a high exchange surface with very little thickness (lower than a millimeter) in order to have a high-speed passage.

The Mash

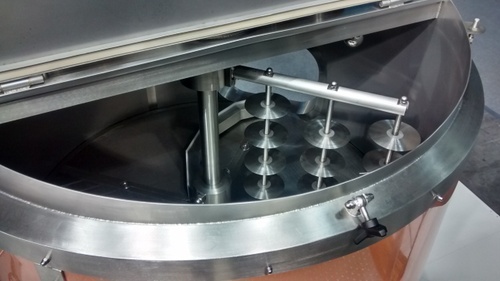

Simatec brewhouses use the free mash system. The agitation system is made of a double paddle at 45 degrees with a span equal to the diameter of the tank. It is installed in the lower part of the tank and grants the optimal mixing of the mash to avoid any risk of dead zones forming with really concentrated mashes.

Grist filtration

Grist filtration

Grist filtration can really make or break a quality wort. The parameters of a good filtration include filtering speed, rapidity of initial clarification, constancy of the grist temperature, the extraction efficiency and the low hot oxidation.

Grist filtration is where Simatec thinks it has made the largest technological strides. The controlled flow Simatec system, with controlled temperature, constant flow of sparging water and mixing of the upper part of the grist is unique in its genre. The filtration system is made by a separated filter that is short and broad to provide the best possible filtration ratio. The result is a system of control of the filtrated flow by volumetric pump and a control of the depression that keeps the flow constant during the entire filtration.

The flow is reduced at the very beginning to have a fast initial recycling of clarification (3-4 mins), which increases, creating a little depression during the central phase, which is the most difficult, without a rake. The goal is to give filtration a repeatable, defined time (about 1 hour) and a really low decrease of the grist temperature. A constant flow of the filtrated brew allows for a constant flow of sparging water, which leaves a few centimeters of water constantly on the grist during the entire filtration. This provides constant and low pressure from the top down in order to avoid packing too much on the filtering bed.

An optional system of instantaneous heating of the sparging water can compensate for the loss of the temperature of the grist.

Finally, the mixing system in the upper part of the grist keeps 10 centimeters of grist motionless on the bottom in order to have a filtration panel that is always active. In the meantime, the upper part is mixed by means of special plows or rotating disks, in order to increase the extraction efficiency. Simatec says this system allows for efficiencies higher than 85 percent and sometimes higher than 90 percent.

Whirlpool

Simatec brewhouses use a paddle whirlpool system located within the boiling tank, rather than a separate tank. This patented DUPLEX paddle allows for production of the mash, the boiling and the paddle whirlpool all within the same tank.

The DUPLEX sits at 45 degrees for an adequate mixing of the wort, while rotating in the opposite direction, placing them horizontally in order to have a paddle whirlpool. The paddles’ rotation is automatic and takes place only because fluid dynamics forces the effect. In this way, at the end of the boiling, by just reversing the paddle rotation, it is possible to perform a fast and efficient whirlpool, without transferring the wort into a specific tank.

The all-in-one effect

Tying the entire modular Multi-Brew system together, Simatec claims a brewery can complete a cooking cycle in 6 hours and 30 minutes; two cycles in 8 hours and 30 minutes and four cycles in 16 hours. If you have three tanks, you can have three cycles in 10 hours and 30 minutes and six in 18 hours or 10 in 24 hours.

Simatec promotes its brewhouse for those who are in the building phase because the addition of a new multifunctional tank does not require any modification of the existing setup.

So, there you have it on the Simatec system. If you’ve read this far, you are likely interested in brewhouses. Before you go, you may want to give a look at our #brewhouse story archives.

http://t.co/gJZev7ZuPj… http://t.co/Xrw8h4hQpe

RT @robertdolci: Efficient brewhouses: The modular, multifunctional Simatec http://t.co/Yt9D4LP4tx via @craftbrewingbiz @aizoongroup #mfg #…

Joshua Bennett liked this on Facebook.

Ignacio Jose Montenegro liked this on Facebook.

Rives Borland liked this on Facebook.

Don Gregory liked this on Facebook.

Jerry Elliott liked this on Facebook.

Jared Read liked this on Facebook.

Efficient brewhouses: The modular, multifunctional Simatec Multi-Brew http://t.co/ftuxKu2nDj

Efficient brewhouses: The modular, multifunctional Simatec http://t.co/Yt9D4LP4tx via @craftbrewingbiz @aizoongroup #mfg #iot #breaking

RT @CraftBrewingBiz: Efficient brewhouses: The modular, multifunctional Simatec Multi-Brew http://t.co/CLtck8x2CC @simatecimpianti