There are a scary amount of applications where a craft brewery uses CO2 in the brewing, packaging and serving process: maintaining proper head pressure on tanks for process applications; moving beer or product from one tank to another; carbonation of that product; scrubbing oxygen prior to packaging; packaging of beer in a can filler or keg racker operation; pre-purging brite tanks after cleaning and sanitization; and pouring draft beer at a restaurant or pub. That’s just for starters.

Currently, as we all know, there is a global shortage of CO2 that is affecting the beverage and food processing industries. Craft brewers are certainly feeling the pinch. For example, Massachusetts’ Night Shift Brewing announced it’s mostly switching to contract brewing, and one of the main factors calculated in this decision was the carbon dioxide shortage. That’s one solution. There are others. In fact, there are actually ways to captures carbon dioxide in the brewery with something like a CO2 recovery system. I’ll be up front: This type of equipment is not cheap. In this episode of Unfiltered, craft brewers cited that these recovery systems can easily cost $70,000 to $120,000 (and the one below is probably more expensive). That’s a lot of moolah, but the CO2 shortage is making these system more attractive. How?

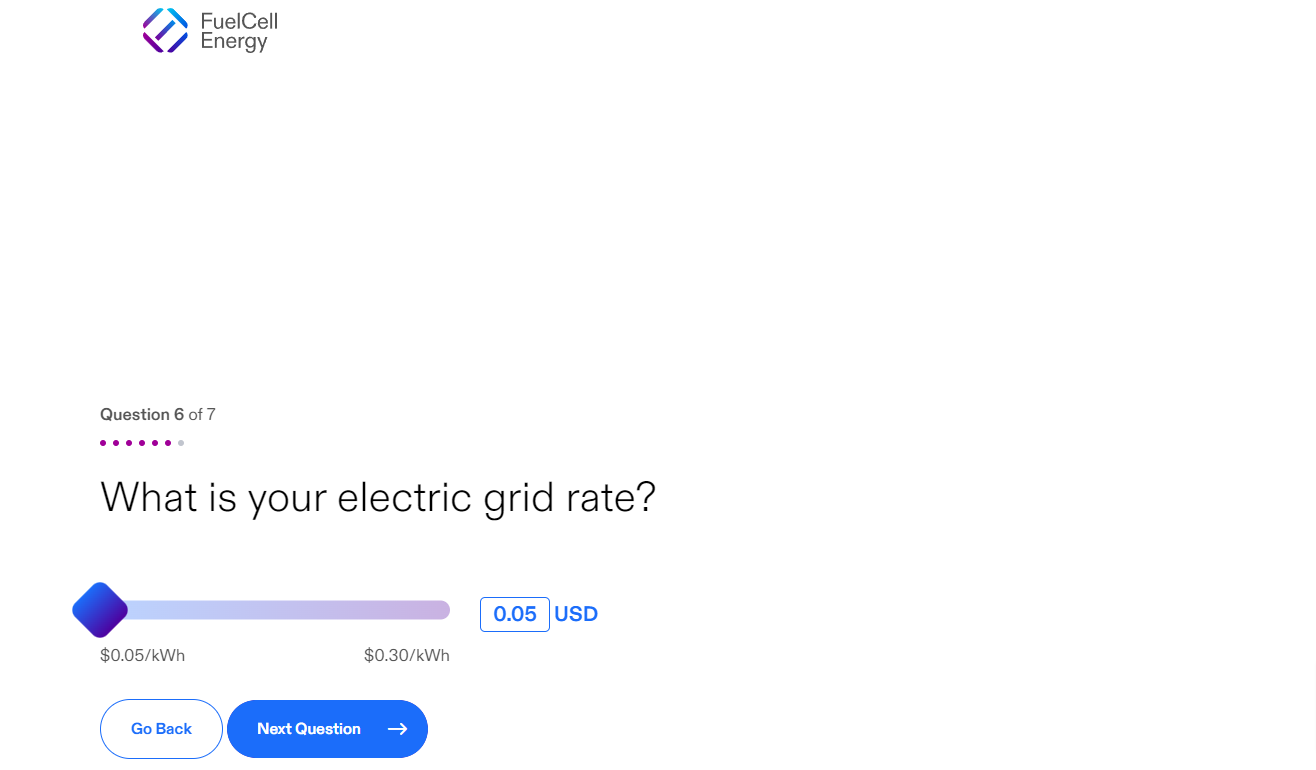

Well, let’s find out how much money and CO2 you could be saving. That should help you start to consider it. FuelCell Energy Inc. — a global leader in manufacturing stationary fuel cell energy platforms for decarbonizing power — recently announced a new Carbon Savings Calculator for companies looking to gain greater insight into how the carbon dioxide produced by their operation across Scope 1 and Scope 2 emissions can be recycled and reused in their business. This approach provides an alternative to purchasing CO2, oftentimes from much higher polluting sources such as ethanol facilities, and can help avoid the business risk of rapidly rising CO2 prices and scarcity of supply.

From the press release:

“In the food and beverage industry there is tremendous and ever-growing demand for beverage grade CO2, however, traditional CO2 suppliers currently are and will continue to be challenged for the foreseeable future to meet that demand,” said Bob Yeoman, Executive Vice President of B&R Compliance Associates. “Working with FuelCell Energy to upcycle CO2 for food and beverage applications could provide dramatic benefits like cost savings, independence from traditional sources, and availability.”

While FuelCell Energy’s scalable carbon capture solutions are pretty large and top of the line, this CO2 calculator can be used by anyone. Just make sure you have some info like your electric grid rate and how much you currently pay for CO2. Learn more about FuelCell Energy alternatives over here, and then enjoy these other articles on the CO2 shortage and recapture technologies.

Leave a Reply

You must be logged in to post a comment.