SensoTech’s LiquiSonic line of analyzers measure the concentration or density in almost every kind of liquid inline. The technology is based on a high-precision measurement and a very fast and stable analytical method, that is independent of conductivity, color and transparency of the process liquids. The measuring results are available online and are updated every second.

LiquiSonic consists of up to four sensors and one controller. The devices are connected digitally, which guarantees high, drift-free measurement accuracy and interference-free data transfer at distances of up to 1,000 meter (3,280 feet). Interruptions caused by wiring or extensive recalibration when a sensor is exchanged are now things of the past.

The ultrasonic measurement process produces results of exceptional quality when applied in the field. It can deal with extreme processing conditions such as temperatures between -100 °C (-150 °F) and +200 °C (375 °F) and process pressures of a few mbar to 500 bar (7,000 PSI).

LiquiSonic allows multiple component measurements to be carried out, such as the independent measurement of scrubbing liquids and the dissolved salt in gas scrubber applications or the alcohol content and residual extract in beer.

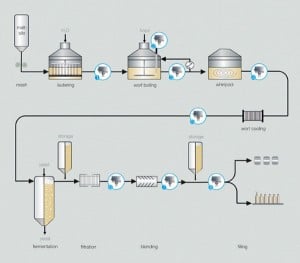

Specifically for you, craft brewer, LiquiSonic Plato is a highly sophisticated inline analyzer for concentration and density measurement of beer and wort in breweries. The system allows control and monitoring of concentrations at different points throughout the brewing process.

Modern manufacturing technologies not only ensures precise measuring results, they also enables convinient operation of the device. This includes the simultaneous presentation of original gravity, extract and alkohol as well as product or brand identifiers.

Due to the complexity of the lautering process the results can be very different from brew to brew, so the goal of the LiquiSonic Plato is to eliminate such fluctuations and stabilize the results on the highest possible level. In outlet of the lauter tun of the brewery or the mash filter, LiquiSonic Plato is used:

- To control the lautering process, for accurate determination of the sparge water point;

- To determine the averaged extract content (initial extract in the wort boiler) directly by combining with a flow meter (EXtrACT-Totalizer).

In the wort boiler of the brewery the LiquiSonic Plato is used to:

- Control the extract concentration during the complete boiling process;

- Determine precisely the final wort concentration to minimize the steam utilization.

For internal boilers a sensor is provided, which can be installed in the boiler directly. This sensor is of a special design minimizing the impact of deposits. Moreover, the sensor is with increased immersion length available and can be equipped with a cleaning head. For external boilers the sensor is installed directly within the circulation pipe between the wort supply pump and the heat exchanger.

There is a ton of other places along the brewing process where LiquiSonic fits in. Be sure to head SensoTech’s website to see if it makes sense for you.

Shade Tree Beer Brewers liked this on Facebook.

Exceptional! Measure liquid density in real time with LiquiSonic Analyzers http://t.co/RBXfIJQrQv

Keith Whitfield liked this on Facebook.

Ivan Sievens Blasini liked this on Facebook.