Bursting at its stainless steel seams, Avery Brewing Co. in Boulder, Colo., anxiously awaited its transition into a new state-of-the-art facility in North Boulder when we sat down to chat in early 2015. The brewery, which got its start in early ’90s as the fortunate result of Adam Avery’s home brewing experimentation, is now cranking out 50,000 barrels a year, running brewing and bottling operations 24 hours a day at full production capacity. Quality Manager Rob Christiansen took a rare free moment to share some of the trials and tribulations of maintaining sanitation quality and keeping hectic brewery operations spic and span.

With an estimated 85% of its fermentation outdoors in the foothills of the Rockies, Christiansen explained the old facility had “a lot of unique challenges.” In addition to seasonal wintery conditions, all tank connections were manual, requiring brewers to grab and stretch hoses up to 100 feet to manually connect to a tank.

“A lot of the beer was traveling a lot of distances, so we always had major concerns about micro pickup in that brewery,” Christiansen said. To mitigate this concern? “We over-clean and overcompensate … but one of the things we were having a hard time with [years ago] was quick validation… We were turning tanks so quickly and we needed to brew into them as soon as they were clean…and making sure takes time with microbiology plates.”

These challenges likely sound familiar to other rapidly growing microbreweries.

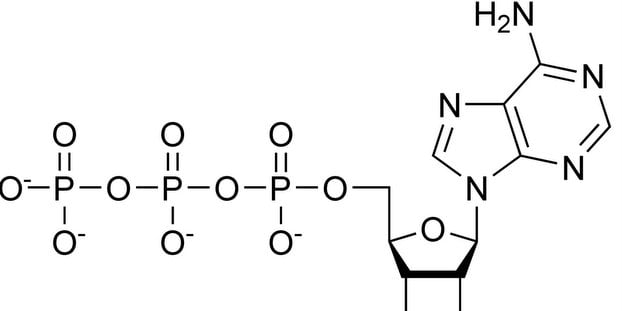

Flash back to 2011, when then Pinch Hitter/Brewer (his title, not ours), now Cellar Manager, Dan Strevey proposed using a new technology that he had become familiar with in his Fermentation Science courses at Colorado State University. The technology was ATP testing — a simple and affordable test method used by most food and beverage processors to verify cleaning effectiveness in seconds.

RT @HygienaUSA: RT @CraftBrewingBiz: The story of @AveryBrewingCo quality assurance ATP testing. Some good insight from @HygienaUSA http://…

Juan Carlos Sibaja Delcore liked this on Facebook.

Todd Parker liked this on Facebook.

RT @CraftBrewingBiz: The story of @AveryBrewingCo quality assurance ATP testing. Some good insight from @HygienaUSA http://t.co/wwEUa3KSLC