University of California, Riverside (UCR) Research Engineer Chan Seung Park has developed an inexpensive sensor (estimated cost is a measly $10) to measure the content of the gas coming into water heaters and other gas-powered devices and adjust the air flow to optimize energy production by combustion. This devise is perfect for the brewing industry.

The higher the energy content level (also known as the BTU level or Wobbe Index), the better the natural gas, but depending on the source, energy content levels can vary by more than 10 percent, said Park. Power plants use a bulky $50,000 machine to analyze the energy content of natural gas and adjust air flow accordingly to improve the combustion efficiency, Park said, but that machine is way too big and expensive for most businesses, let alone households.

Years earlier, when Park worked for a refinery, he created an algorithm to easily measure the octane levels in gasoline. The project was abandoned because his then-employers didn’t see a market, he said, but he thought about that project when he came to UCR and began considering a way to measure the quality of natural gas.

Through his research at UCR’s Winston Chung Global Energy Center, Park developed an algorithm that lets him predict energy content levels in natural gas “by measuring something else [in the gas] that is easy to measure. We call it predictive measurement,” he said, “which enables intelligent combustion or smart combustion.”

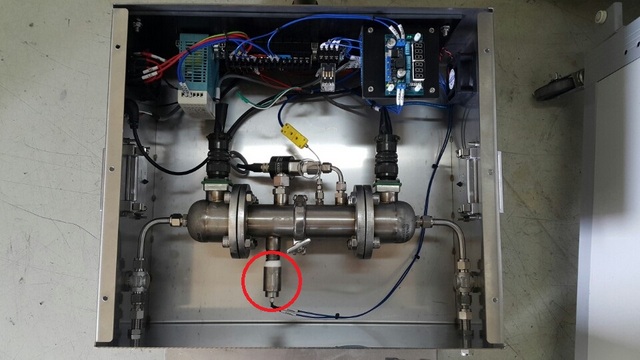

The “something else” he measures is a trade secret, but it seemed so promising that in 2017, Park won a $45,000 Proof of Concept grant from UCR’s Office of Research and Economic Development to build a prototype of his smart combustion device. A year later, his prototype has helped him win a $1.5 million grant from the California Energy Commission, or CEC, to create a device that can reduce natural consumption by at least 10 percent in breweries.

Turns out, beer makers use a lot of natural gas to heat up the steam boilers that make their product, so do coffee makers and other food producers, Park said, which is why the CEC is looking for an easy, inexpensive way to reduce natural gas consumption.

The grant gives Park three years to create a sensor that works on steam boilers at Rough Draft Brewing Co. in San Diego, with the goal of mass producing the devices for other breweries, food producers and even home hot water and pool heaters.

To learn more about this awesome initiative, head over to the UCR website.

Leave a Reply

You must be logged in to post a comment.