The future direction of the barley industry was the emphasis of discussion at the Feb. 15 Golden Triangle Barley Update in Conrad, Montana. The triennial event is a collaboration between MSU Extension and industry representatives. Nearly 75 growers and industry representatives from across the Golden Triangle braved the winter roads on the way to Conrad to hear from experts.

Kent McVay, agronomist with the MSU Southern Ag Research Center in Huntley, started the presentations with an overview of current research they are conducting on crop rotations and fertilizer efficiency effects on malt barley production characteristics. Laura Demmel, National Association of Conservation Districts from Bozeman, discussed a new national initiative to highlight the sustainability of barley production, called Field to Market.

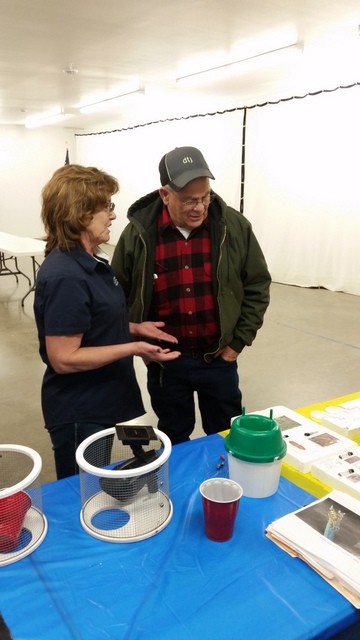

The staff from the Western Triangle Ag Research Center were on hand over the lunch hour to discuss their efforts in monitoring insect pests across the Golden Triangle. After lunch, Dr. Anton Bekkerman, MSU Ag Economist, discussed the decision-making process growers need to utilize when determining which crops to plant. Dr. Jamie Sherman listed her goals of breeding a high production low protein barley, with a better enzyme makeup, quicker hydration without increasing field sprouting and eventually a winter barley. On the recommendation of growers, she may start looking into low temperature germination and seedling survivability in cold climates.

Collin Watters, Montana Wheat and Barley Committee, gave an informative discussion covering industry trends. In the past, the US exported more barley, but now is exporting malt. Most of the malt export goes to Mexico, where it used to make beer and then exported back to the United States. Nationally, feed barley use has been replaced by corn. The United States is becoming a smaller producer on the world level, as Ukraine and other former Soviet Bloc states are trying to dominate world supply. Saudi Arabia and China are the largest barley importers in the world. Watters discussed how there have been many changes in brand ownership, market share, and companies over the recent past. Domestically, the import and craft brewer share of the beer market has been increasing and beer has been losing market share to spirits and wine in the U.S. market since 2000.

On the bright side, world stocks are declining slightly, after several years of oversupply. Food barley can be bred to have a high percentages of heart healthy beta glucans and that market is growing, especially in Asia. Researchers are currently developing new flavored barley varieties to give beer new taste options. Organizations are working on increasing the amount of malt exported, but this might continue to decrease our domestic sales. Collin Watters wrapped up his presentation by discussing the possible development of packing houses in Montana, which could lead to more feedlots thereby increasing barley use as feed.

An industry panel consisting of Alan Slater from AB-InBev, Kris Smelser from Miller Coors, Reed Gibson from Malteurop and Ryan Pfeifle of Farm Power Malt gave overviews of their operations and answered producer questions. They all agreed one advantage malt barley had in the current production system is that malt barley breeding programs were very open, sharing, and collaborative. They rely heavily on public/private partnerships and not one company withholds germplasm for their own proprietary use. There is an industry effort to develop a lower protein, higher yielding dryland variety to replace Hockett, which has had some issues with saturation in the malt process. They are not going to replace Hockett completely, but are looking for options to blend with it.

There is also a push to look for varieties that improve sustainability, especially in water use for marketing purposes. They all discussed how consumers are placing more emphasis on source verification and sustainability and we may see an organic beer in the future. Everyone encouraged producers to continue to utilize crop rotations to offset lost contract acres, especially because there are no guarantees those contracts will return to historic levels. They did comment on the fact that the last few years have been hard on producers and local company staff, and everyone hopes they can reduce farm storage time and improve returns to producers.

The event including lunch and refreshments were made possible through the generous support of the Montana Wheat and Barley Committee, American Malting Barley Association, Malteurop, Miller Coors, Centrol LLC and MSU Extension.

Leave a Reply

You must be logged in to post a comment.