For most small breweries, space is always at a premium. Brewing is an equipment-intensive business — brewhouse, fermenting and brite vessels, packaging equipment, cold storage, barrel aging — not to mention a bar, offices, COBRA rooms and forever onward. That’s what caught our attention about MPE’s Chain-Vey custom-designed, bi-directional conveying solution. It’s designed to help navigate that busy brewery with flexible, layout-friendly malt and grain conveying.

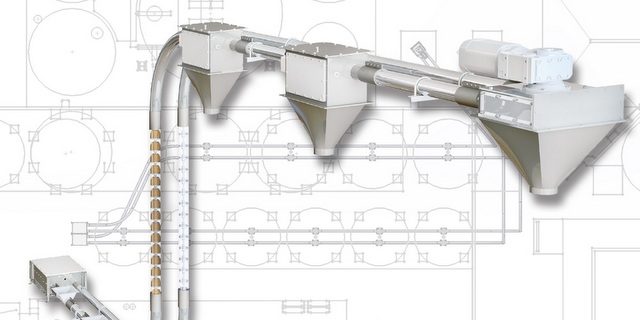

Instead of using the more common, space-sensitive, flex auger straight line systems, the Chain-Vey offers a flexible solution that moves products horizontally and vertically in one system. Let’s make it real simple: Augers can only go straight, and this puppy turns corners and goes up and down, and it looks futuristic and cool doing it (just watch the video above). The system also combines multiple inlets and discharge points to be used for base and specialty malts alike, providing total clean-out between malts without the need for any operator cleaning.

‘The conventional way to convey malt and grain is to use screw augers,” explained Chris Smyth, sales engineer for the Chain-Vey Division “These systems use a tube or PCP pipe to convey materials through the brewing process. The downside to these systems is that they use an actual screw that turns and conveys but is locked in a fixed position, unable to change direction and are labor intensive and require a stock pile of spare parts. This provides an issue in small spaces or unique layouts, often times requiring a brewery to have multiple flex augur systems to convey product forward, then vertically or horizontally — or different angles. The MPE Chain-Vey can hit angles from 5 to 90 degrees.

“The Chain-Vey system eliminates these issues by allowing product to travel in multiple directions within one system,” continued Smyth. “One Chain-Vey can replace up to three flex auger systems. Additionally, the Chain-Vey comes standard with dry cleaning technology — wiper discs and air knives at the discharge to clean chain and puck, assist in discharge and close to zero percent of the product put in is wasted on the discharge. This essentially eliminates any downtime for a brewing facility.”

The MPE Chain-Vey is a revolutionary conveyor designed for transporting not only malt and grain, but food, chemicals and other bulk powder products without degradation or declassification. We contacted the makers at Modern Process Equipment Corporation and asked them a few questions. We got a hold of John Eiting, director of Chain-Vey sales, specifically. Here are his responses.

CBB: This is more than just a conveying system for malts, right? Can it be used to move other products besides malt and grain in the brewhouse?

Eiting: The Chain-Vey application moves powders, limestone, chemicals, raw food products, cereal, coffee, beans — you name it. Specifically, for the brewing industry, the Chain-Vey conveys the malts and is capable of moving spent grain. An additional benefit to having a Chain-Vey is that it’s fully capable of having multiple inlets/discharges, which is a nice perk for specialty brews.

CBB: You’re selling a system here, so what does it entail? Where does the flexibility come in? How will the evaluation and setup process work?

Eiting: MPE Chain-Vey is a component of a brewery system. The Chain-Vey conveys product within the facility. The flexibility of the Chain-Vey versus other conveyors comes from its ability to move product both vertically, horizontally and multiple directions within the same system, which is important when you’re working in tight spaces and unique layouts. The main components come fully assembled, and the installation fits together all of these components, including the turn-around unit, the drive unit (motor), the piping and the CIP chain and pucks.

CBB: How is the Chain-Vey operated, and what about maintenance and upkeep?

Eiting: The Chain-Vey systems require no individual operator. The system runs on a motor, and brewers can run the speed depending on their needs. The Chain-Vey is the most reliable and robust tubular drag conveyor on the market and is considered a “no touch machine, requiring zero unscheduled maintenance. Additionally, the Chain-Vey system requires very few consumable parts, typically less than $100 a year. An estimated 80 percent of Chain-Vey’s in use are still running on original critical parts, and the design consumes at least 60 percent less energy than pneumatic conveying systems.

Beargrylls Sum liked this on Facebook.

Jonathan Cahoon liked this on Facebook.

RT @crsimp01: Chain-Vey is a supreme malt-moving conveying system for breweries https://t.co/vBneX9ImNn via @craftbrewingbiz

Chain-Vey is a supreme malt-moving conveying system for breweries https://t.co/vBneX9ImNn via @craftbrewingbiz

John Agee liked this on Facebook.