At Pack Expo in Chicago last week, Roberts PolyPro, a product brand of ProMach, introduced its first fully automated can handle applicator for craft beer and spirits packaging lines that applies handles to four-packs or six-packs at a rate of 10 cases per minute.

The THA240 automated can handle applicator works with the core can types commonly used — slim, sleek and standard sized. The machine features a pneumatic gantry system to pick the handles out of a magazine and place them on the rim of the cans in an intermittent operation. During each pick and place cycle, the gantry system picks either six four-pack handles, or four six-pack handles from the magazines and places them on the cans.

“Designing a machine that make things easy and keeps things moving was our goal. We wanted to provide brewers with a handle applicator that supported them as they scaled up production for off-site distribution but minimized, as much as possible, manual interaction,” said Roy Tetreault, vice president and general manager at Roberts PolyPro. “The THA240 is also designed in a way that makes it a relatively easy add to current operations without suffering much, if any, disruption.”

Operation explained

Changing over can handles in the applicator is quick and simple. There are no change parts or modifications required to switch between 12-oz or 16-oz standard sized cans or handle styles, allowing customers the freedom to easily utilize all sizes if desired without incurring a lot of time or cost. Also, minimal change parts are required to switch from the standard can to the slim or sleek sized cans.

With both sides of the magazine filled, the machine can operate continuously for approximately 30 minutes before the handle magazines need to be replenished. The handle magazines can easily be reloaded through the magazine access door while maintaining operation to minimize downtime.

Other product highlights include easy-to-use controls, which allow the operator to quickly start and stop the machine, saving additional downtime. Additionally, the robust steel frame provides a stable, low vibration platform for long years of service, and its small footprint, only 55 by 70 in., conserves valuable floor space.

Can handle highlights

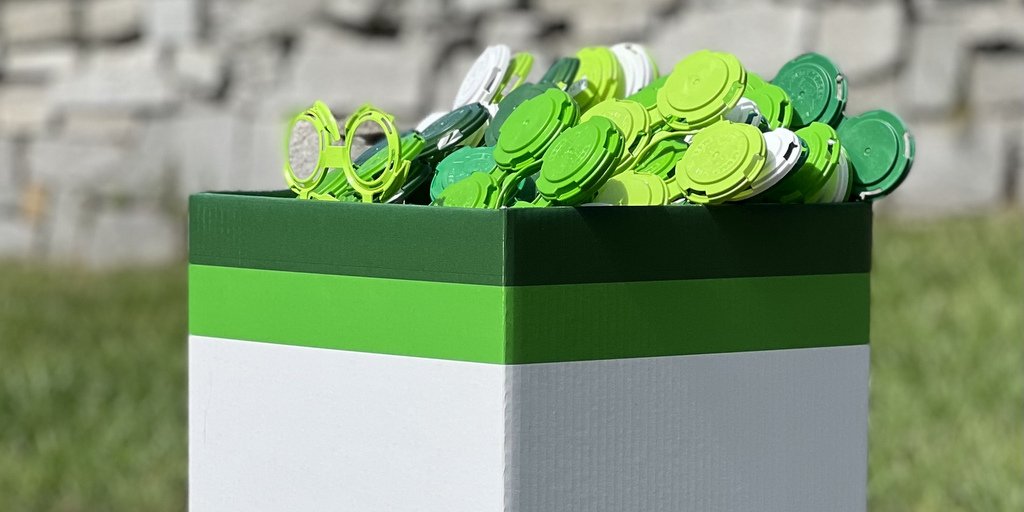

Roberts PolyPro four-pack and six-pack HDPE #2 handles for the THA240 are available in 32 standard colors and feature an open top design, so no moisture accumulates between the can top and handle. The handles are 100 percent recyclable and use up to 30 percent less plastic, making for a more sustainable product.

Leave a Reply

You must be logged in to post a comment.