The feature Two Roads actually appreciates most is that the unit takes a mere 10 minutes or less to warm up, compared to its hour-long wait with the old system. If there is a human error (someone forgets to turn on the glue unit), it takes just a few minutes to rectify the mistake and move forward. In addition, there is no more need to assign valuable personnel to check on glue levels and keep them properly filled. Rather than constantly starting and stopping and performing glue nozzle replacement, the new system frees up operator manpower for more productive upstream or downstream tasks.

According to Concialdi, the automated aspects of the new equipment are a huge help, protecting the production line from human error. For example, if the unit does not dispense glue within an hour, it automatically shuts off. Before, there were instances where the unit could be running at high temperature over the weekend.

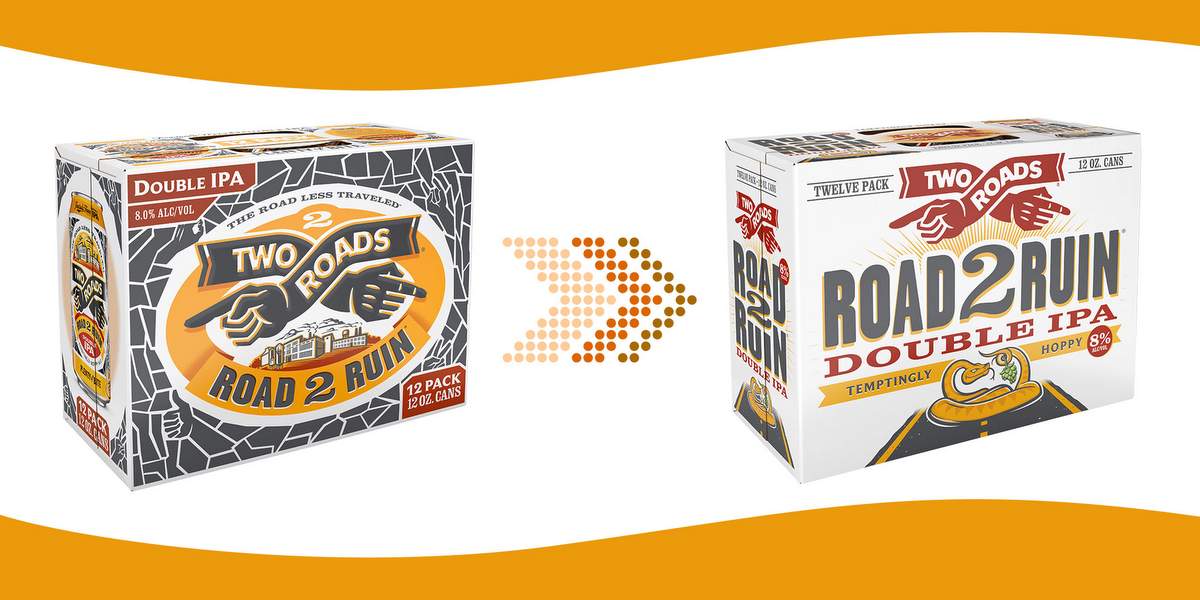

Most recently, Two Roads added an InvisiPac Pattern Control System, which gives it better control over glue dispensing to seal major and minor flaps on its cardboard cartons. The new integrated pattern controller allows operators to accurately place precise amounts of adhesive and save money by converting from a solid bead to a stitched bead with the push of a button. The integrated pattern controller is another key automation feature, with all of the programming, startup and shutdown right at the operator’s fingertips.

“For the glue pattern, we can just type in numbers. We now have recipes, and the machine remembers everything. We have the ability to change things on the touchpad rather than dealing with dials and just hoping to get the settings right. The complete automation of the Graco unit is something we are really loving.”

Installation was quick and painless. Graco provided the equipment as a complete plug-and-play unit, and the old system was easily removed. After training, Two Roads was given operating manuals and contacts for technical assistance.

The wow factor

Since the installation at Two Roads, Astro Chemical’s Chester Duff reports that he has installed numerous systems.

“There’s a significant wow factor,” he says. First of all, the equipment has a sleek industrial design – it looks like an ATM or perhaps R2D2. It comes up to temperature so fast, which is a boon to many plants. Rather than having to pay overtime for a production person to come in to turn on the system to be ready for an 8 a.m. shift, an operator can flip the switch and a low application temperature hot melt can come up in just a few minutes.

“The other wow factor is down the line when you realize you don’t have to touch it,” Duff says. “It’s called the InvisiPac system for a reason. It is invisible to the operator. You never have to touch it. You can go about your business and do other things.”

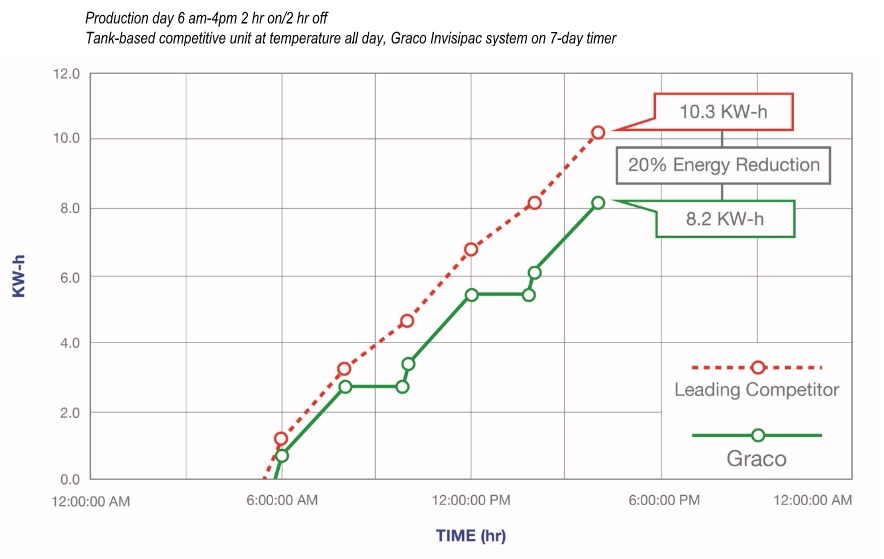

While energy use was not a specific issue for Two Roads, the equipment’s reduction of energy costs is drawing a great deal of attention at other plants. The new technology uses much less energy on startup. The hoses use less energy than industry standard; additional hose insulation provides up to 66° F cooler surface temperature, resulting in less lost energy to the environment. The system’s features allow users to improve their production sustainability, demonstrating they are leaving a smaller footprint when manufacturing a product.

Concialdi concludes by saying that Two Roads has been extremely satisfied with the Graco equipment, support and service. He gave a special shout out to Anthony (Tony) Horelik, Graco’s local area sales manager, who personally oversaw installation and would not leave until the customer was up and running. He jokes that Tony thinks of the machines as his babies and comes back from time to time to check on how they are doing. Tony insists he stops by for the beer.

“I believe he would do anything for us, but his products run so well that he doesn’t have to. I have recommended these units to plant personnel at other breweries, and I especially like to point out how their automation solves the problem of human error.”

References

[1] Understanding and troubleshooting hot melt adhesives, TIP 0304-74, ISSUED – 2000, The Technological Association of the Pulp and Paper Industry (TAPPI)

CRAFT GLUE: @CraftBrewingBiz: Boxing & Packing Case Study w @2RoadsBrewing #ctbeer #craftbeer http://t.co/IGlcwwIoNf http://t.co/zc8KQACrSZ

Hot melt! A Two Roads Brewery production demand case study http://t.co/4dsUXDkY5j @craftbrewingbiz @2RoadsBrewing http://t.co/UfcRblDkHl

As featured on @CraftBrewingBiz: “Fast Growing Brewery Uses Graco’s Hot Melt Technology to Meet Production Demands.” http://t.co/32oeEkTkty

Hot melt! A Two Roads Brewery production demand case study http://t.co/rTQHzgXlU2

Jared Read liked this on Facebook.

Hot melt! A Two Roads Brewery production demand case study http://t.co/WlttJqipxH via @craftbrewingbiz