Mobile canning

Maybe you don’t have the space or funds for the additional equipment needed to efficiently package your beers in a new container, like aluminum cans. In this case, one trend that is exploding in the industry is mobile canning.

The equipment and process usually handles about 25 to 35 cans a minute, depending on whether it’s a 12- or 16-ounce run. There is the full-service option where Mobile Canning supplies everything, including the pre-labeled cans, can tops, four- or six-pack holders and cardboard flats. If a brewery is looking to hit retail with a lot of cans, the company can also provide an option where the brewer purchases a bulk order of pre-printed cans and Mobile Canning would arrive to simply provide the canning services.

The only potential restriction is the on-site layout.

“While the line has been specially configured to be mobile, we still need to be able to get the line at least somewhat near the beer,” said Andrew McLean, co-owner of Michigan Mobile Canning, a franchisee of Mobile Canning Systems. “There aren’t too many locations we can’t reach, but that’s a consideration as we’re meeting brewers and touring their facilities. However, as we told them, if you want your beers in cans, we’ll figure out a way to make it work. When there’s beer to be had, brains can get pretty creative.”

A canning line “is a big asset to be sitting there, but also the inventory as well, having to sit on a truckload of cans,” said Pat Hartman, co-founder of Mobile Canning Systems. “It’s a lot of capital and space if you are only making 1,000 bbls a year, and a portion of it is in cans, you can go through a truckload of cans, but it will take you five years. And that’s just one label as well.”

The economies of scale and the lower order counts can allow a brewer to be more nimble and experiment with a variety of new/existing/seasonal brands in cans. This is where that shrink-sleeve labeling comes in handy.

“A shrink sleeve allows you to work with the smaller volumes that make sense for a brewery that’s decent size and wants to make a seasonal,” Hartman said. “We can run 15,000 cans at a time without breaking the bank. So still within numbers where the brewery is still going to be able to make some money off what they are doing.”

Integrated solutions

Not having your own packaging equipment is only efficient up to a point. When filling equipment is your next move, look for solutions that can fill multiple needs.

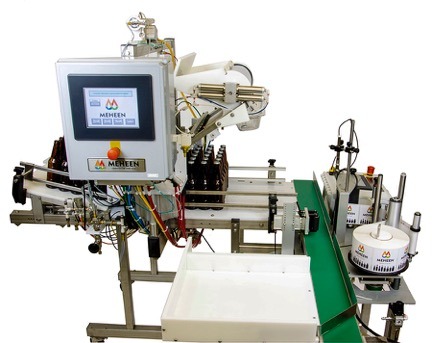

The Meheen M-Series, for example, offers a complete, integrated bottling solution (rinsing, filling, crowning, and labeling system). In addition, Meheen also provides carbonating technologies in the form of the Meheen Tank Manager, designed to help manage carbonation and temperature controls.

Meheen can customize a complete filler/labeler system to accommodate any size and shape glass or aluminum bottle. Customers can choose from two-, four- and six-head filler systems for any type of beverage product they wish to bottle and label at up to 2,300 bottles per hour depending on the bottle size/volume.

The M series fillers are designed to optimize limited brewery floor space and turn it into a large scale production zone. The system is mobile and can be wheeled into place for bottling and then wheeled away and stored when not bottling. This allows very efficient use of the limited floor space of a typical craft brewery.

Meheen fillers are pneumatically powered for long-term reliability. With no motors, gears or bearings to maintain, there is a low cost of ownership. The touch screen operating controls help brewers monitor and control fill rates, counter pressure, CO2 pulse/fobbing and other aspects of the brewer’s filling process at the touch of a button.

As for labeling, Meheen’s ML bottle labeler is versatile with the ability to apply full wrap, front-only, or front-and-back labels at a rate of up to 60 labels per minute. The air assist rotary container guide is unique in its design and ensures a high quality, consistent application of the labels on dry, moist, and cold substrate surfaces. Additionally, the ultrasonic bottle detection provides reliable bottle sensing regardless of the beverage container, material, or color. The ML bottle labeler is available integrated with the Meheen bottle filler or as a stand alone labeling system.

If you’ve read this far, you care about packaging. Or, you fell asleep with your face on the keyboard. Either way, we recommend scrolling through our packaging archives for something else to read.

Packaging your #craftbeer on a budget? Here are some solutions to consider! https://t.co/CXF2iPhfYH @craftbrewingbiz

Packaging on a budget: Four solutions your craft brewery should consider https://t.co/joCDXUU1C0

4 packaging solutions your craft brewery should consider https://t.co/go8Ne3lQio

RT @CraftBrewingBiz: Packaging on a budget: Four solutions your craft brewery should consider: https://t.co/lHQK4wgOz0

RT @GreatBeerNow: 4 packaging solutions your craft brewery should consider https://t.co/iEKCCMgTcY via @craftbrewingbiz

4 packaging solutions your craft brewery should consider https://t.co/iEKCCMgTcY via @craftbrewingbiz

Karli Olsen liked this on Facebook.

#CraftBeer #CraftBrewing #Beer #BeerBiz Packaging on a budget: Four solutions your craft brewery should consider https://t.co/dYaRqAPTTd

Joseph Rushton liked this on Facebook.

4 packaging solutions your craft brewery should consider https://t.co/oiW7aGnYXM via @craftbrewingbiz

RT https://t.co/S90r9alox3 InsuranceGuyKR: RT CraftBrewingBiz: Packaging on a budget: Four solutions your craft b… https://t.co/5f34MSW1xD

RT @CraftBrewingBiz: Packaging on a budget: Four solutions your craft brewery should consider: https://t.co/lHQK4wgOz0

4 packaging solutions your craft brewery should consider https://t.co/LA8oh9Y3yk