Guinness has been brewing since the 18th century, so the company knows a thing or two about the business of beer. While your goal as a craft brewer may not be global beer baron status, readers can certainly learn something valuable by watching how Guinness goes about said business.

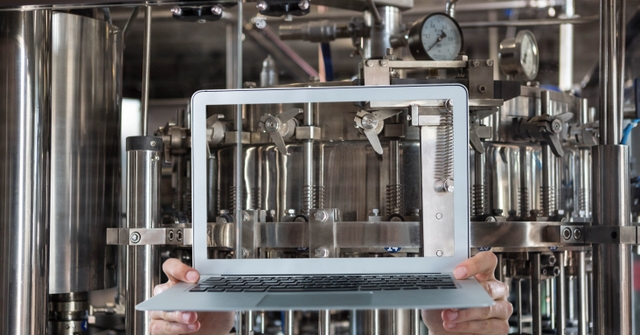

Recently, our friends over at GEA told us they had been working with Guinness on a big project — specifically the cold processing area at the famous St. James’s Gate brewhouse. GEA is not unlike Guinness in the fact that it’s one of the world’s most famous turnkey brewery manufacturers (owners of the equally famous Huppman brand).

GEA sent us over a case study on its job with multinational alcoholic drinks producer Diago (owners of the Guinness brand). That excellent feature is below.

The phoenix rises in Dublin

Wishing to consolidate its brewing operations at St James’s Gate in Dublin 8, Ireland, Diageo recently invested €169 million ($190 million U.S.) in the world-famous home of Guinness. Knowing that sustainability and investment are key elements of long-term success, the site is now one of the most technologically advanced and environmentally sustainable breweries in the world.

To enhance the production of Guinness Flavor Extract (GFE), which is exported all over the world to enable the local production of Guinness, Project Phoenix involved the implementation of new raw material intake and handling systems, a new brewhouse, a new cold process area as well as modifications to the existing cold process area to integrate the existing plant with new, significantly improved utilities and expanded capacity. GEA’s scope involved the new cold process area, to update the existing cold process area and the cold end of the new GFE process, and incorporate new brands into the St James’s Gate portfolio with additional processing equipment.

Organization by GEA

To kick-start the project, GEA took on most of the design and procurement work for the new cold process area and provided a team of engineers who tackled the site installation work, commissioning and validation, as well as the modifications. Local GEA experts also took responsibility for the overall site management, including the coordination of installation and commissioning activities, liaising with the civil contractors and ensuring compliance with the site’s rigorous health and safety requirements. The schedule was aggressive: design work started in July 2012; the first new vessels were installed in February 2013; and the cold process area received its first wort from the new brewhouse in August that year.

World of #BeerCraft: Learn how macro brewer Guinness builds its cold process area http://t.co/pPkVICA6o1 @CraftBrewingBiz

Learn how macro brewer Guinness builds its cold process area http://t.co/cAixBpULNL via @craftbrewingbiz

RT @CraftBrewingBiz: Learn how macro brewer Guinness builds its cold process area. @GuinnessUS http://t.co/c5ZWfn8rgM

World of Beer Craft: Learn how macro brewer Guinness builds its cold process area #beer #feedly http://t.co/VFR5v3M7rp