Pipe. Maybe not the sexiest subject matter in the brewing industry, some might say, but those folks have probably never heard of polypropylene (a thermoplastic polymer and one of the most versatile plastics around).

In pipe form, polypropylene is touted for a) its durability conveying corrosive fluids, b) being light weight and c) its ability to handle extreme temperatures. In a brewery, it can be used to transport everything from glycol to potable water.

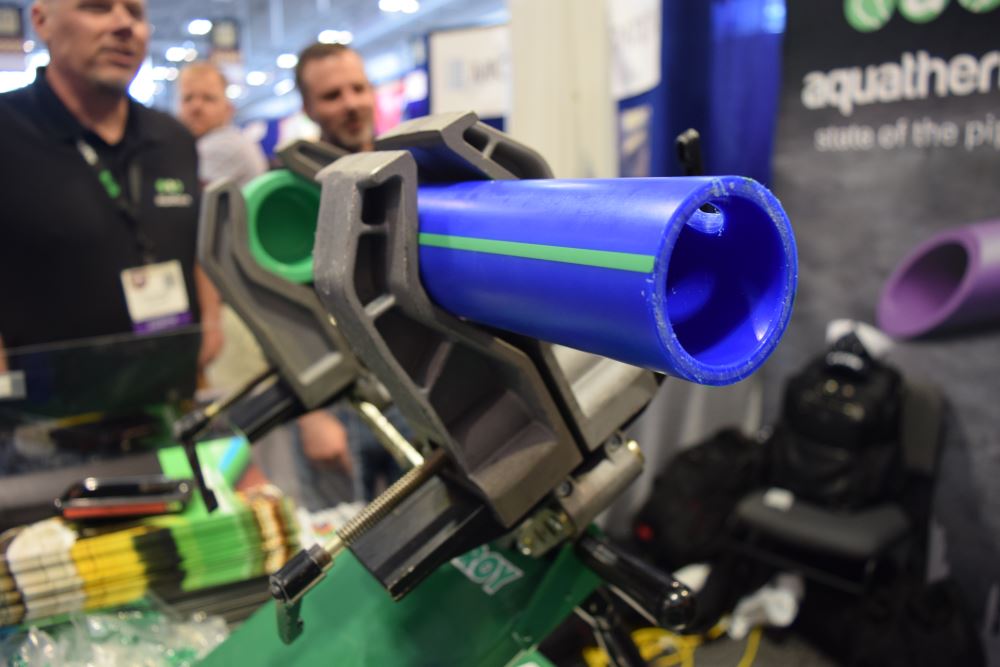

One of the sexiest brands in the polypropylene pipe industry is Aquatherm and its polypropylene-random pipe (PP-R) product. The company’s colorful green and blue pipe systems are certainly striking when you see them in a brewhouse.

“It looks really cool,” confirmed Ron Rajecki, marketing specialist with Aquatherm. “It’s also incredibly functional. It’s chemically inert. There are no VOCS. No leaching. No scaling. Its heat fusion process means leaks are virtually unheard of. It lasts for decades, and it’s recyclable. Unlike metal pipe, it has a natural insulation value. It even qualifies for LEED v4 credits, but the big headline here is it can help you craft a better brew.”

More than one hundred craft brewers are currently using Aquatherm for a variety of reasons. Aquatherm PP-R pipe is chemically inert and hydrophobic. It does not leach any chemicals into the water, glycol or other liquids that it carries. It does not corrode, erode or scale like steel or copper pipe. The flow rate when the pipe is installed will still be the flow rate decades from now. In addition, the heat fusion process used to join Aquatherm pipe does not rely on mechanical connections or use any glues or solvents that could potentially release chemicals or VOCs into the liquids being transported. Plus, polypropylene pipe has a very long lifespan (typically 60 years), and when it is ready to be replaced, the old piping is 100 percent recyclable. Double plus: polypropylene pipe is not subject to the tariffs recently imposed on imported steel and aluminum.

“In fact, the price of polypropylene pipe has remained remarkably stable and predictable over the years,” said Rajecki. “Engineers planning mechanical systems and contractors bidding on them can be assured the price of Aquatherm pipe will not fluctuate based on any tariffs or other upheavals in the commodities markets. This gives owners of craft breweries assurance that they will not either find pipe unavailable when they need it or be subjected to sticker shock when the price of their steel or copper pipe unexpectedly skyrockets.”

Let’s learn about those colorful pipe choices

Aquatherm is a German company. It’s been engineering polypropylene piping systems for more than four decades. For breweries, it offers three main products. Aquatherm Blue Pipe can be used for heating and cooling as well as carrying coolants such as glycol. Aquatherm Green Pipe is NSF rated for potable water and food grade applications, and Aquatherm Lilac Pipe is designed for recycled and reclaimed water systems. That “cool” Blue Pipe above is what’s really generated buzz from Aquatherm in American breweries.

“Our entry to the market really sprung from use in glycol cooling systems,” Rajecki noted. “Breweries typically run their product cooling systems at a lower temperature than would be used in many other applications. Aquatherm polypropylene-random pipe is chemically inert and has a very high resistance to the chemicals in antifreeze. In a properly designed and installed system, PP-R pipe will transport glycol for decades without any degradation in strength or performance.”

Aquatherm has led the polypropylene pipe revolution in America. In fact, it worked with regulatory bodies to secure the necessary approvals for its use here. Beginning with Aquatherm’s arrival in North America in 2005 and the United States in 2007, the company worked with regulatory bodies and code agencies to secure the necessary approvals for polypropylene piping’s use here. These included the National Science Foundation (NSF), ASTM International (formerly known as the American Society for Testing and Materials), and the International Organization for Standardization (ISO).

The Aquatherm website features a dozen case studies from breweries across the United States using its products, including Wise Man Brewery in Winston-Salem, N.C., Smith and Lentz Brewing Co. in Nashville, Flathead Lake Brewing Co. in Big Fork, Mont., and Founders Brewing Co. in Grand Rapids, Mich. These breweries turn to Aquatherm for a variety of reasons — from chemical to food-grade applications — but also for one main reason — quality results.

“Craft brewers cannot and don’t want to compete with mega-breweries on volume. They are going to secure their place in the market through quality,” said Rajecki. “Using Aquatherm pipe is just one of many steps craft brewers can take to ensure their product is of the highest caliber. And with an expected lifespan of 60 years, considerably longer than metal pipe, it is a step that will pay off for decades to come.”

Melissa Luelling says

Aaron Luelling