In our book, new software and tech innovations were the big story around the 2019 Craft Brewers Conference and BrewEXPO America trade show floor last week. From inventory and POS streamlining to brewing efficiency and quality control, there are more valuable, powerful solutions to fit every size and shape of craft brewery than ever before. Here are some standouts.

Ekos adds POS integrations to boost your taproom efficiency

Taprooms are a driving force of revenue in the craft brewery and cidery community today, so why not fully optimize the processes around them? With Ekos’ taproom update they are bringing new life to the way users manage their taprooms through software. These updates were all created to support a large need and customer request for a point of sale integration. With the launch it will sync with both Arryved and Square POS solutions, with more coming in the future.

This update will offer a solution for inventory management from behind the bar, consistency between multiple taproom locations, and hours of time savings to allow more time with customers.

The taproom isn’t an office cubicle and Ekos realized that. Gone are the days when taproom managers have to compile all the data from multiple spreadsheets at closing time to hand over to the accountant. With this integration Ekos becomes the central hub for all the user’s financial data. All the numbers coming through the POS system flow into Ekos, then automatically to the accounting platform. Rather than having to look at Ekos and their POS reports to reconcile data, everything will now live in one place – saving hours of late-night manual reconciliation. This translates to large savings for brewery and cidery owners by saving large amounts on accountant costs.

With success comes scale, something else Ekos also wanted to address. The taproom brings in so much revenue, keeping potentially critical financial information on sticky notes is not a scalable or an accurate system. Users with multiple taprooms now have a consistent way of reconciling financial information across all locations. Syncing point of sale data into your management software and accounting platforms allows for less possibility of human error when entering information for multiple taprooms, creating a better overall user experience for your entire team. This update helps taproom staff spend less time on paperwork and get back to spending time with their customers.

Ekos’ integration with Arryved and Square point of sale solutions creates a new level of time-savings that users will enjoy. This update helps users simplify their taproom processes with an all-in-one solution. Ekos provides checks and balances to the process, helping minimize financial errors caused by manual entry. The added efficiency and standard processes will help create a cohesive and easy to use way for users to collect their taproom numbers.

Particle’s Internet of Things platform leads to zero waste at Oktoberfest

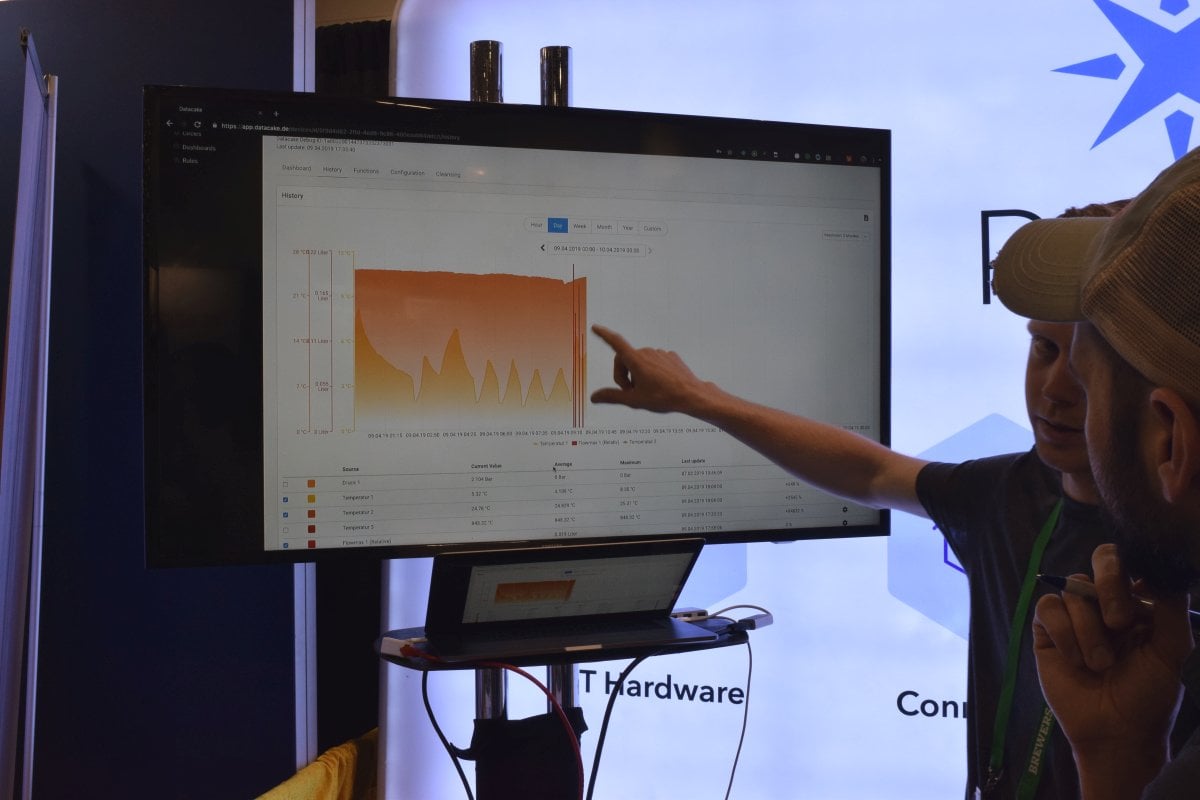

Here is an interesting new partnership between the sensor gurus at Datacake and the Internet of Things (IoT) experts at Particle that’s paving the way for breweries to vastly improve efficiency.

In 2018, Datacake and Particle worked with a well-known Munich brewery to maximize operations in their tent at Oktoberfest. It took 10 minutes to install sensors on the beer taps. The result: The brewery dispensed 276,153 liters of beer with zero downtime over 17 days due to smart sensors developed by Datacake, and powered by Particle’s Internet of Things platform.

Datacake’s smart sensors helped the brewery anticipate problems before they became larger issues by sending detailed and real-time analytics on the machine’s performance, which enhanced business overall:

- With the detailed analytics, the brewery could keep detailed records on the tap’s beer flow, temperature and air pressure.

- The smart sensors automatically reported diagnostic issues to owners, allowin them to correct issues before they became larger problems.

Precision Fermentation expands BrewMonitor pilot program nationwide

Precision Fermentation, a leading biochemistry technology solutions provider, announced today the successful growth of the pilot program for their flagship BrewMonitor system into a total of seven states across the US. The program offers craft brewers the chance to try data-driven fermentation for up to 60 days free of charge, providing a robust trial for successive fermentations and multiple beer styles. The program has also generated invaluable feedback regarding the efficacy and value of the company’s Internet of Things (IoT)-driven fermentation monitoring solution. New installations in many additional states are planned for Q2 2019.

“When craft brewers learn that they can now track dissolved oxygen, pH, gravity, pressure, and temperature from any web-connected phone, tablet, or PC, they become very interested to try BrewMonitor for themselves,” said Jared Resnick, CEO of Precision Fermentation. “Beyond interest in how our technology works, most are excited to monitor, for the first time, exactly how their fermentation decisions are affecting the final product. Continuous sampling and real-time data visibility expands creative and operational possibilities for a brewing team, including much greater control of quality and consistency and dramatic improvements in day-to-day efficiency.”

Leveraging existing fermentation tanks, BrewMonitor offers brewpubs, microbreweries, and regional craft brewers unprecedented visibility into the fermentation process. Real-time monitoring automatically alerts team members about problems the moment they occur, and recorded data streamed from successive fermentations enables direct comparisons that help ensure consistency for flagship beers, seasonals, and any other beers that need to be repeated.

The pilot program was originally rolled out in the southeastern U.S., but since its launch in November 2018, the company has received regular inquiries from brewers throughout North America. Requests are being accepted on a first-come, first-served basis from anywhere in the continental U.S.

BREWD adds new Brewery Production functionality

Fermented Labs, creator of BREWD, the fastest growing provider of software to the craft beer industry, released new software to help craft breweries handle the production aspects of running a brewery.

BREWD Production features the following: Raw Material Management, Recipe and Brew Process Management, complete Batch Management, historical views of everything brewed, and availability in 14 languages.

Early Access will be open to any brewery and is available for free for three months for a limited time. After that, Brewd will off an introductory cost of $29/month as more features are offered. Participants in Early Access will have the unique opportunity to directly influence the roadmap by sharing their feedback about existing and future functionality.

“This represents a significant milestone for us.” stated John Jackovin, CEO of Fermented Labs, “We have been working towards this point for a couple years now and it feels great to be here.”

“$29/month is considerably less than any other system out there.” Dave Jensen, CTO of Fermented Labs commented, “We want to build BREWD with our customers. We hope that our introductory offering for Production encourages participation and feedback.”

Today is the last day to earn a three month free trial. Email [email protected] for the discount code.

Beer30 version 5.0 streamlines everything

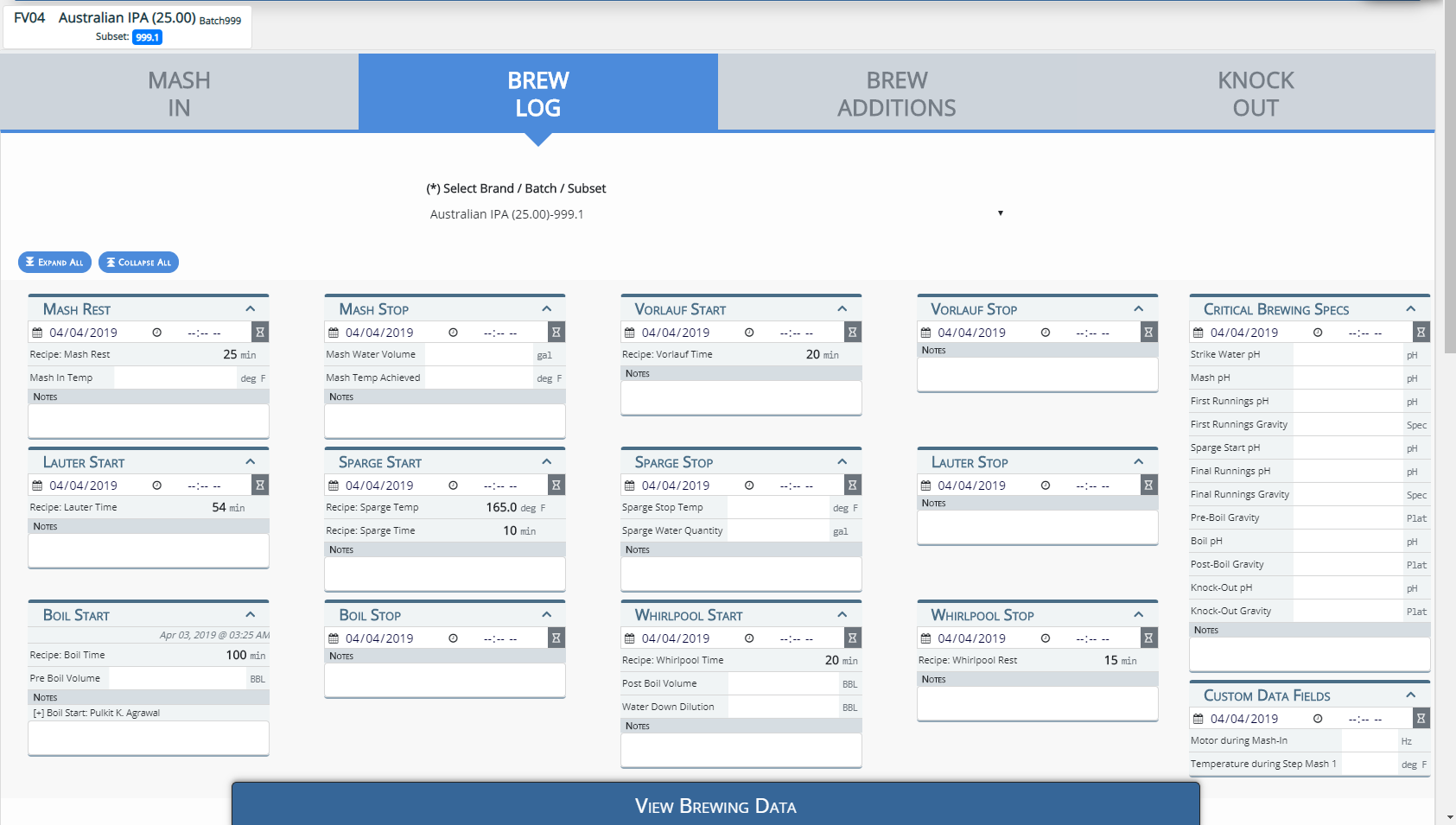

The folks at Beer30 updated their Brew Page after listening to customer feedback, streamlining from 18 modals to now just four key areas: Mash In, Brew Log, Brew Additions, Knock Out.

The new Brew Additions page is set up to allow you to add in First Wort Hops, Boil Hops, Adjuncts, Kettle Finings, Whirlpool Additions, and any Hop / Adjunct Substitutions. You’ll want to watch this YouTube video for more info.

Thermo Fisher Scientific streamline quality testing with GENESYS UV-Vis Spectrophotometers

Craft beer brewers now have access to an economical solution designed to streamline quality assurance testing and achieve batch-to-batch consistency with the new Thermo Scientific BeerCraft software package for the Thermo Scientific GENESYS 50 and GENESYS 150 UV-Vis Spectrophotometers. Together, the two provide American Society of Brewing chemist-quality testing methods for more than 20 beer attributes, including color, bitterness, protein, sugar, carbohydrate, polyphenol levels and more. Unlike other solutions, BeerCraft software is configurable for use with reagents and chemistries from many vendors.

“Batch-to-batch consistency is critically important to the craft brewing industry, so we’ve developed quality assurance and quality control analytical capabilities for the craft brewing process,” said Karnel Walker, director of UV-Vis and NMR spectroscopy products at Thermo Fisher Scientific. “Our new BeerCraft software seamlessly integrates a library of beer-specific testing methods with the highly configurable and user-friendly GENESYS UV-Vis spectrophotometers, reducing the dependency on sensory testing methods such as visual, taste or smell inspection.”

Leave a Reply

You must be logged in to post a comment.