The number of craft brewers in America is now more than 7,000. With so many new establishments on the rise and amateurs aiming to become master brewers, brewery owners and managers need to understand the essential requirements of cleaning. Without a proper cleaning program in place from day one, hygiene issues, quality lapses and customer complaints can negatively impact your brand before it becomes big.

The number of craft brewers in America is now more than 7,000. With so many new establishments on the rise and amateurs aiming to become master brewers, brewery owners and managers need to understand the essential requirements of cleaning. Without a proper cleaning program in place from day one, hygiene issues, quality lapses and customer complaints can negatively impact your brand before it becomes big.

Cleaning is key

One of the biggest risks for anyone new to the brewing industry is ignoring cleaning protocols. Taking shortcuts increases the risk of cross-contamination, which can result in safety issues, a recall of your prized brew and even temporary or permanent closure for your brewery. Even after cleanliness issues are resolved, it may be difficult to regain the trust of your customers.

Unfortunately, quality issues are not always obvious. Microbiological problems might not show up for two to three weeks depending on your fermentation process and the aging involved. Incomplete or inefficient checks at this late stage could lead to substandard beer entering the marketplace. Proper hygiene is critical for producing and reproducing high quality beer, free of any unwanted flavors or characteristics. Consistency and quality are the benchmarks for any good brewery, and proper hygiene programs allow brewers to achieve them.

Regardless of brewery size, brewers should set up key performance indicators (KPIs) and an in-depth microbiology score to provide a baseline of current microbiological results. Regular micro-testing provides the analytical data to determine whether a brew is infected. With a simple micro-testing procedure, you can develop extensive analytics to assess the health and purity of your operation.

Common and persistent soils

Throughout the brewing process, organic and inorganic soils can form on the walls of tanks, kettles, lines and valves, as well as any surface of the production plant itself. Cleaning is not just a critical component of a well-managed brewery — it is also an essential precursor to effective sanitization. Proper cleaning ensures protection against any type of residential soil that can interfere with the action of sanitizers, and in some cases neutralize their effectiveness.

At each step of the brewing process, the formation of different soils requires specific chemistry, cleaning in place (CIP) programs and frequency of cleaning to remove them. Your sanitation program should define tailored cleaning procedures for each piece of equipment to deal with the broad range of soils, some of which can be burned onto surfaces. Depending upon your brewery location, various water hardeners may contribute to mineral scale buildup.

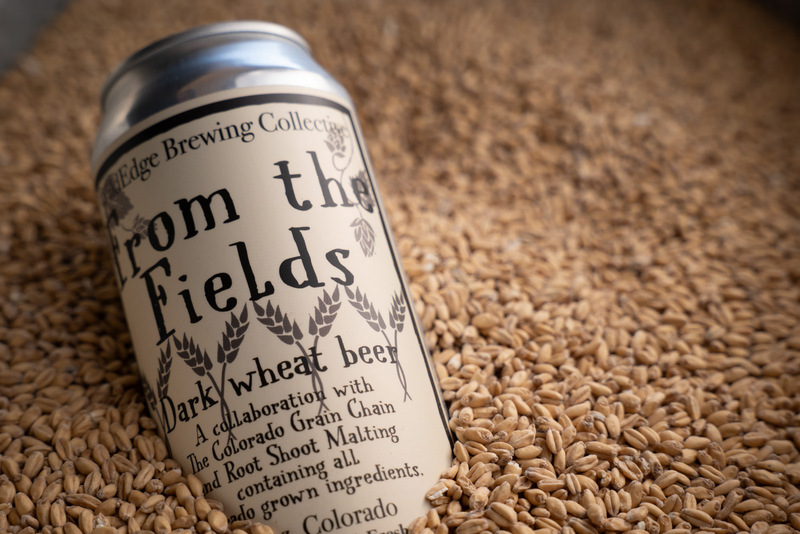

Every brewery should clean equipment after every use, and if tanks or vessels sit longer than 24 hours, it’s imperative that they are re-sanitized. While breweries face similar challenges with soils, one key difference occurs with the style of the brew. Adding more hops, more malt or more wheat will contribute to the complexity of cleaning. The degree of difficulty in removing soils varies depending on how long beer ages, whether hot or cold surface deposits are involved and the ingredients that are added. If your business changes the ingredients it uses, re-evaluate your program to confirm that you are still cleaning effectively.

Knowledge on tap

To give your business a competitive edge, rely on a trusted chemical supplier to provide expertise and help guide your process. Procedures and protocols are supported by this knowledge, and your team can rest assured that experts are available to help with any cleaning or microbiology issues that arise. Expert consultants can assess your current programs and challenge your operations to lower water, utility, energy and chemical costs to optimize and increase your productivity.

Hygiene is both a fundamental requirement and a key business driver for craft brewers. When fully aware of their hygiene needs, brewers can limit soil contamination while ensuring safe operations and helping run the business more efficiently. Although this can initially seem like a daunting prospect, making smart hygiene solution choices and creating a comprehensive cleaning and sanitation program will allow your business to exceed consumer expectations and deliver the beer that reflects your hard work.

Troy Matteotti is the sector director, Beverage and Brewing at Diversey, a leader in smart, sustainable solutions for cleaning and hygiene. For more information on brewing solutions for your business, click here.

Tom Larsen says

They also need great insurance in case they claims follow!

Brew Review says

Not clean? Not beer.

Mike Nelson says

No names but there are a couple of small breweries here in Colorado Springs that I have received skunked beer that I know was sanitation. If this home brewer can keep his equipment clean than pro brewers should definitely,be able to.

Matthew Peterson says

Sanitation is Job #1