The brewing industry has always embraced innovation to meet market demands, each time revolutionizing the business. In the United States, the first major revolution came in the 1870s, when beer became a popular beverage with more than 4,000 breweries each producing their own unique beer. However, limited infrastructure and product consistency constrained beer sales to local markets only. The Industrial Revolution changed everything: advances in technology, transportation and economics enabled breweries to shift from local to national — and eventually global — business models. This resulted in massive consolidation, and the number of U.S. breweries shrank to as low as 90 in the 1970s . While consumers reaped the benefits of higher quality and consistency, they lost out in terms of product variety.

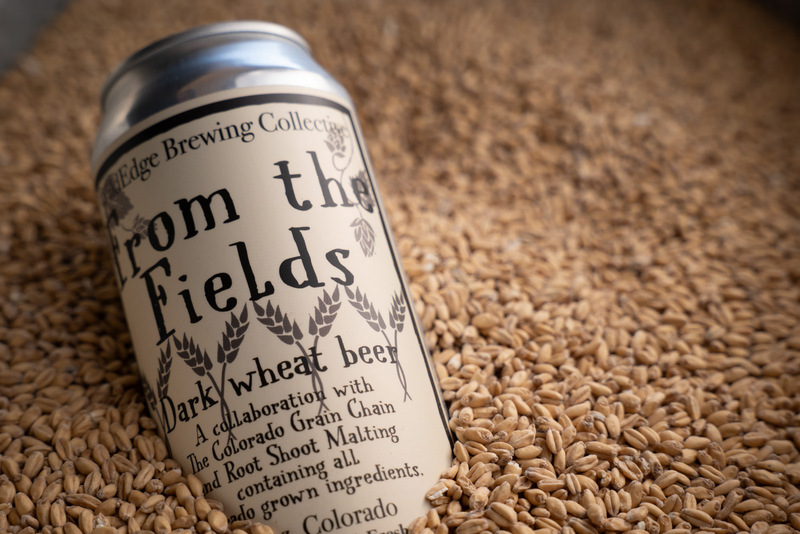

Today, we are in the midst of another brewing revolution. The innovative thinking behind craft brewing has brought the industry full circle, with more than 5,000 U.S. breweries currently in operation. Thriving alongside their macro-brewer counterparts, craft brewers are producing unique beers that combine the locality and style diversity of the past with modern industrial brewing techniques, ushering in a new beer market that features high quality, consistency and unique flavor.

All of these revolutions have been the direct result of changing consumer trends. Historically, pale lagers became popular when consumers first starting drinking beer at social events. Today, beer drinking has evolved into a socially sophisticated event, akin to drinking wine or cocktails. This in itself is due in large part to consumer demographics having shifted to include more minorities, women and young consumers. Beer consumers have also become more health-conscious, technologically savvy and “beer educated” due to the rise of craft and homebrewing. While this means current beer consumers are now more discerning than ever, the silver lining is that these same brand-conscious consumers are extremely loyal and willing to pay a premium for a compelling product.

This is a follow up to last week’s feature “Brewer’s yeast evolution: Update on modern breeding techniques for craft beer”

Brewer’s yeast evolution: Update on modern breeding techniques for craft beer

However, not all breweries can make a compelling product, and the result is that roughly 50 percent of all microbreweries in the United States have failed since 1980s . What is clear about those that do thrive — compared to those that don’t in this competitive market — is that successful breweries are problem solvers and early adopters of future trends. Naturally, capitalizing on trends of the future requires adopting a “Brewery of the Future” perspective. Back in the 1800s, this meant incorporating ground-breaking technologies such as sterilization, refrigerated mass transportation, bottling/canning and external carbonation. Today, it means taking outside concepts and technologies from other industries and research institutions to challenge existing processes, infrastructure and operating philosophies — in short, using blue-sky thinking to drive innovation.

With this wider horizon of knowledge, brewers are beginning to conceptualize an all-encompassing brewing platform. Essentially, a Brewery of the Future will merge traditional brewing with revolutionary technology, delivering high product quality by optimizing flexibility, sustainability, efficiency, yield and manufacturing costs, and by meeting the ever-changing demands of regulators and discerning consumers. Although the concept of building the Brewery of the Future might sound daunting and perhaps a little risky, small steps taken today can be the drivers of innovation tomorrow.

A step to the future: yeast optimization

One such small step within the reach of all brewers is optimizing the yeast they use in their beer. In addition to ethanol, yeast-derived compounds make up over half of beer’s flavor and aroma, yet yeast (as compared to hops or malt) remains a black box to many brewers who are hesitant to try something new or different. And that’s truly a shame, as yeast can be both product innovator and problem-solver; its impressive untapped biodiversity can be leveraged for product enhancements, while non-GMO development techniques such as selective breeding can optimize those strains to be high performers in the brewery. Ultimately, innovative yeast can be fully customized to a brewery and its beer, right down to specific desired parameters in fermentative performance, processing, storage, flavor and aroma — and all without compromising quality or brand identity.

For example, yeasts that reach attenuation faster increase brewery capacity and efficiency without any capital investment. This can be done by selecting and/or breeding traits, such as overall faster metabolism, growth at a wider range of temperatures, quicker replication times and higher tolerance to osmotic and alcohol stress. Furthermore, yeast may also be developed to optimize starch saccharification or eliminate off-flavors, thereby reducing processing times and storage requirements. For example, vicinal diketones (VDK) are produced during the fermentation process, giving beer the aroma of butter and butterscotch, and are generally considered a defect or a sign of bacterial contamination. Innovative yeast strains with reduced VDK production and/or increased VDK re-absorption would allow breweries to shorten (even eliminate) the diacetyl rest period.

Innovative yeast can also be leveraged to produce unique beers with novel flavor and aroma profiles. Seasonal flavored beers are the second most popular craft beer and present a great opportunity for breweries to offer unique, limited-time and premium products, such as citrus beers in the summer and spiced beers in the fall. Brewers are already experimenting with the addition of fruits, herbs and spices, harmonizing these flavors with hops and malt, e.g., accentuating citrus fruit with Citra hops. Innovative yeast developed to produce or transform specific aromas themselves can help boost the potency and perception of various additions (hops or otherwise) while rounding out flavor profiles.

With beer sales (particularly lagers) plateauing or declining in some global regions and market saturation becoming an issue, breweries must leave no stone unturned in order to remain profitable; yeast can be both today’s problem-solver for making cost-competitive, higher-quality beer and tomorrow’s product innovator and diversifier — and all of this is possible simply by harnessing its untapped biodiversity potential. Those who ignore this potential lose the opportunity to transform the industry, while those who can ride the wave of innovation toward a Brewery of the Future, with innovative yeast at the helm, have a chance to reap the rewards twofold: better profits for brewers and better beer for consumers.

Jason Hung is Associate Scientific Research Writer at Renaissance BioScience Corp.; Matthew Dahabieh is Chief Science Officer at Renaissance BioScience Corp. Ed Kentish Barnes of KB Solutions (London) Ltd., is a master brewer and chartered scientist, and also brewing consultant to Renaissance. Renaissance’ subsidiary, Bright Brewers Yeast, will be exhibiting, introducing and taste-testing beer made with its first innovative brewer’s yeast at Drinktec in Munich in September.

Leave a Reply

You must be logged in to post a comment.