The Craft Brewers Conference and BrewExpo America is the No. 1 event of the craft beer year (April 10-13), and we want you to be ready to see all of the cool new stuff on the trade show floor. We asked exhibitors to tell us what they will be showing off, and we turned those submissions into these handy CBC previews. See you in D.C.

The craft beer scene currently flourishes on all continents. Depending on the regions and the marketability of the products, a wide variety of technologies is required to complete the brewing process. The common denominator in the process is the fact that product quality and application flexibility must go hand-in-hand with cost-effective solutions.

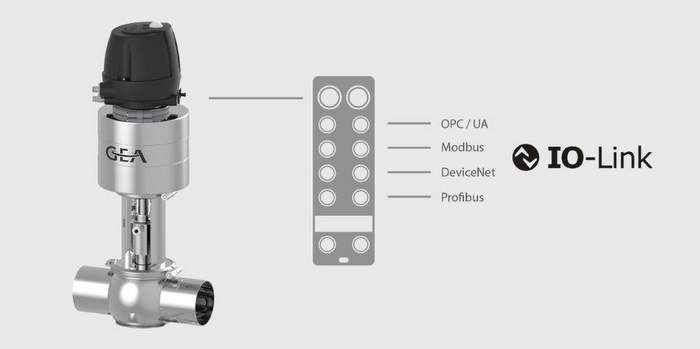

GEA is one of the top brands in brewing technology in the world, aiding in that fight for quality, and a booth visit (booth 2619) should be on your agenda at the Craft Brewers Conference every year.

“It’s exactly because of these requirements that we have developed specialized brewing systems and components that offer modular expansion possibilities and flexible use — and that also can provide flexibility for experimentation by the individual brewer,” says Andreas Holleber, in charge of brewery business at GEA. “We place great emphasis on efficiency in resource input — by which we mean saving energy and water and ensuring outstanding yield.”

In addition to components dedicated to the specific needs of craft brewers, GEA will also present its service concept at the show. This concept starts with a worldwide service network and promises an all-around, trouble-free package for craft beer brewers.

Here are some highlights at the GEA exhibit this year:

A brewhouse for every craft beer

The GEA CRAFT-STAR is designed for medium-sized specialty brewhouses, with batch sizes of 35 barrels (40 hectoliters) of hot wort. Equipped with two, three or four vessels (mash tun kettle, lauter tun and combined whirlpool/wort kettle, depending on the configuration), it is possible to produce seven brews within 24 hours.

The CRAFT-STAR is preassembled and tested at GEA’s Kitzingen facility in Germany as a compact “plug-and-play” system with process piping, instrumentation and an automatic control system. Commissioning on site takes just a few days. With an extract yield of up to 98 percent, the brewhouse’s lauter tun offers top performance with respect to extract efficiency for special malts.

At CBC, GEA visitors will have the opportunity to carefully examine a three-vessel CRAFT-STAR and learn more about its many special features. Beers brewed with the GEA CRAFT-STAR have regularly won awards, most recently at the Great American Beer Festival 2016.

RELATED: Brewing Vessels Reviewed: Cylindroconical fermenters remain a craft beer staple

One unit – five processes with GEA centrifuge skids for craft brewers

The second highlight at the GEA stand will be a GEA centrifuge skid for craft brewers. Available in four sizes, these compact units are multi-functional and are designed for production output of 875 to 87,500 barrels (1,000 to 100,000 hectoliters) per year.

A single machine allows brewers to run up to five processes — an excellent benefit in terms of efficiency. Additionally, the separator’s clarifying output can be adjusted allowing production of both cloudy wheat beer to virtually clear blond lager. With up to 30 percent reduction in production time and 10 percent increase in yield, brewers confirm they make more beer with the piped and pre-assembled skids.

Leave a Reply

You must be logged in to post a comment.