Situated in the famous beer region in northern France, in the Province of Artois near the Belgian border, there has been a brewery in the 330-people village of Bénifontaine for more than 90 years. The Castelain Brewery has been successfully run by the Castelain family since 1966. The brewery is famous for its CH’TI lager, which won a gold medal at the Brussels Beer Challenge in 2013 and a silver medal at the European Beer Star in Munich in 2013.

Since the beginning of 2013, these award-winning beers have now been brewed in a brewhouse engineered by the global brewing experts at GEA Brewery Systems. Recently, the company shared the particulars with us. Apparently, Castelain Brewery set a tight time frame and the main focus was not only on meeting the latest technological requirements, but also covering the increasing international demand with a flexible plant system.

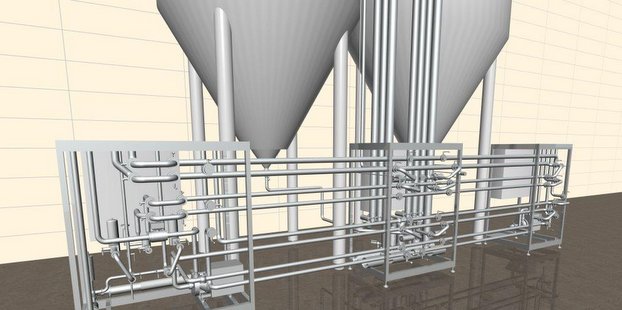

To meet this goal, the GEA Compact-Star brewhouse was selected. The compact, modular, expandable brewhouse concept from GEA Brewery Systems has a number of properties to optimize the process and quality.

On an area of 120 m², brews with an original gravity of 12 to 17 degrees Plato are produced with the Compact-Star with a cast-out quantity of 100 hl cold wort and a filling charge between 1.8 t and 2.3 t. The maximum capacity is seven brews per day. Flexible and versatile features include a three-vessel brewhouse with a 5 t/h Millstar (which is the milling system).

The Millstar has a compact design and ensures steeping conditioning with little oxygen uptake, as well as combining the advantages and benefits of conventional wet and dry milling. The mash is transferred into the mash vessel from below by a Mohno pump. The mashing process can be realized in two ways. The mash vessel is either heated with steam or warm water is added (called infusion mashing).

The lauter tun with a diameter of 4 meters has a lautering surface of 12.5 m² with a free filter area of 14 percent and includes important features from the company’s Lauterstar technology like double-shoe knives and differential pressure measurement. The weak wort can be collected in an insulated tank and the warm weak wort can then be added to the Millstar during the next brew.

The whirlpool/wort kettle is equipped with a Jetstar internal boiler and is individually adjusted to the minimum and maximum cast-out quantity requested by the brewery. Since the brewery produces both top-fermented and bottom-fermented beers, the cooling system is designed as a two-stage heat exchanger. The wort flows to the yeast dosing unit with the corresponding temperatures. With the GEA aeration units, the wort comes to the fermenting room with an oxygen content of up to 12 ppm.

As a specialist for process integration, GEA Brewery Systems integrated some existing process units of Castelain Brewery into the new brewhouse. Thus, the entire system was raised to a uniform technical level and the production process was optimized. The Gearboxx automation system is an open system based on ILTIS. It controls the new Compact-Star brewhouse. For increased security, process monitoring is realized by two redundant servers. The administration of all recipes and of production and laboratory reports can be customized. All production-relevant information can be stored over a period of nine months and provides comprehensive control to the brewery management.

The expandable Compact-Star brewhouse is part of the generation contract of Castelain Brewery. Flexibility of the production equipment in response to a rising demand is thus ensured. With a Compact-Star from GEA Brewery Systems, the brewery in Bénifontaine now certainly has a technical and technological solution that is the best and safest basis for both the present and the next brewery generation.

RT @DenverCicerone: Check out the new brewhouse at Castelain. Here are some details. http://t.co/pNufLqqcqE #beer

Check out the new brewhouse at Castelain. Here are some details. http://t.co/pNufLqqcqE #beer

Check out the new brewhouse at Castelain. Here are some details. @belgianexpert http://t.co/mYxoLSYlsu #WirtzCraft