Like many American craft beer tales, the success story of the Russian River Brewing Co. is the story of a career change. Originally, Vinnie Cilurzo came from a winemaking family in southern California. There he started homebrewing in the late 1980s. He met Natalie, who fell in love not only with him, but also with beer brewing. Today, both are owners and operators of a new brewing facility that is extraordinary in many respects.

Natalie and Vinnie Cilurzo opened their first commercial brewery — the Blind Pig Brewing Co. in Temecula in 1994 — where Vinnie was already experimenting with hops, yeast and original wort. The next major step was in the year 1997, when Korbel Champagne Cellars in Guerneville, Calif., founded the Russian River Brewing Co. The owner of the champagne cellar, Gary Heck, hired Vinnie as brewmaster and initially sole employee.

Strong, stronger, Pliny

For the next six years, Vinnie continued to set the bar high for super-hoppy beers. Pliny the Elder was one of the first commercially brewed double or imperial IPAs in America and won numerous awards over the years. Until today, Pliny the Elder is the most popular beer of the Russian River Brewing Co. Incidentally, the beer name was chosen as a tribute to the Roman philosopher Pliny, who had written about hops 2,000 years ago. However, it goes even stronger: Every February, tens of thousands of beer fans wait for hours to taste the time and volume limited Pliny the Younger Triple India Pale Ale at the Russian River brewery, named after Pliny’s nephew and adoptive son.

No fear of Brett

A second important and unique selling point of the brewery is its barrel-aged sour beers. These beers are aged in used wine barrels with Brettanomyces yeasts as well as Pediococcus and Lactobacillus bacteria. Some of these beers are even blended with cherries, currants and grape must. In order to prevent contamination of the production of bottom- and top-fermented “clean” beers, the sour beer production is hermetically separated from the brewhouse. Many winemakers of the region are still very skeptical, as Vinnie reported with a smile: “For fear of Brett, they do not even set foot in our brewery pub.”

Back to the history of the brewery: In 2003, Korbel decided to exit the beer business and transferred the rights to the name of the Russian River Brewing Co., all beer brands and its recipes to Natalie and Vinnie. The couple prepared a business plan, found two shareholders and convinced 30 friends and family members to invest in their new business. In 2004, the Russian River brewpub opened on Fourth Street in Santa Rosa. In those early days, the brewery had a 25-hl brewhouse. Four years later, in May 2008, a second brewery with a 60-hl brewhouse was opened. Overall, the Cilurzos were able to produce a total annual capacity of about 25,000 hl in Santa Rosa.

Investment goal was nothing less than the dream brewery

Over the years, Natalie and Vinnie gradually paid off all their partners and investors. In 2014, the decision was made to build their dream brewery in Sonoma County. The search for a property took nearly two years, which allowed them time to put together their “dream team” of architects, consultants, designers, contractors and, last but not least, brewing technologists. Finally, they found 15 hectares of unexploited land in Windsor, Calif., and realized their lifetime project — an 85,000-sq m Greenfield brewery with an annual production capacity of 70,000 hl in the final expansion stage. Moreover, the brewery plant encompasses a restaurant with 200 seats, two bars, a beer garden, a tasting room as well as a gift shop.

The brewing line should be as flexible as possible

The brewhouse is equipped with the following components:

- One Colibri mash tun with a diameter of 2.5 m and 74 hl of mash volume

- One Lotus lauter tun with a diameter of 3.9 m

- One Shark wort kettle with a diameter of 2.7 m

- One whirlpool with conical bottom

- One T-Rex mill

The choice of these components reflects the desire to implement a most flexible brewing line with regard to malt type, original wort, hop dosing and batch volume. With the T-Rex it is possible to change at any time between wet and dry milling, a fact that is also used in practice. In addition, numerous rye, barley or wheat malts, just to name a few, can be easily processed with only one mill type. The lauter tun is also resistant to fluctuating original wort, and the internal boiler Shark offers a range of 77 to 97 hl of kettle-full wort per brew.

Dynamic hot wort hopping for dried and green hop cones

Another special feature is the Hop Back dynamic hot wort hopping. In simplified terms, this system consists of a larger dosing vessel with an integrated screen unit. Into this screen unit, the hop cone is fed. At Russian River, for example, these are between 50 kg of dried and 113 kg of freshly harvested hop cone. Subsequently, the vessel is filled with hot wort. The wort enters tangentially and flows through the Hop Back from top to bottom. The holding time of the wort can be set variably via the flow. The hop-flavored wort is then transferred back to the wort kettle. The screen unit reliably separates the spent hops, which facilitates the work in the whirlpool.

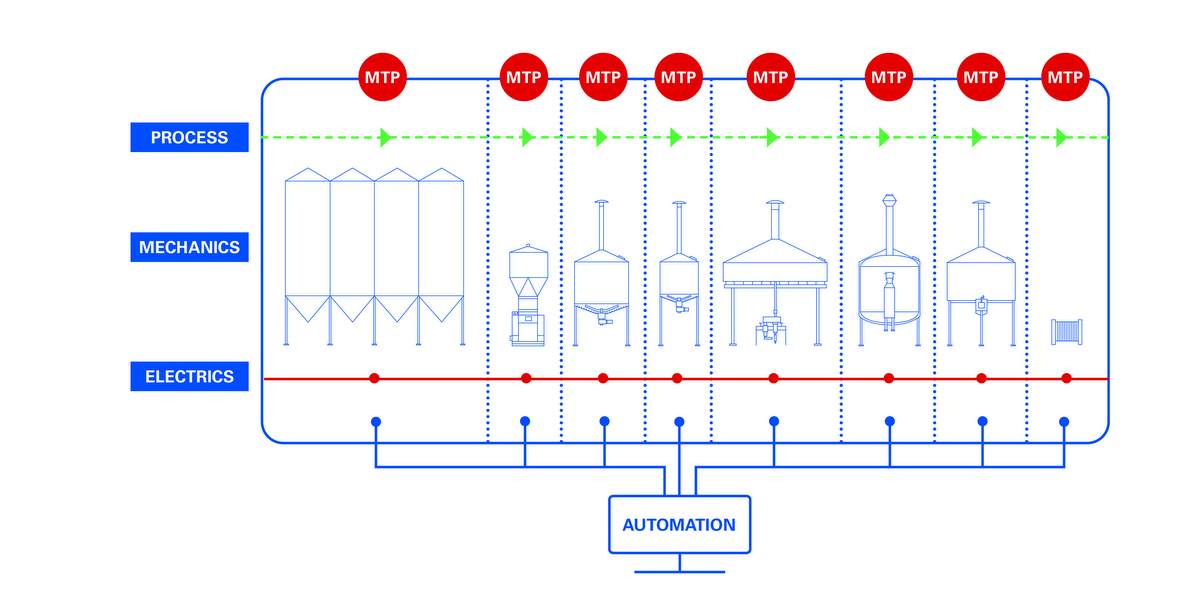

The Cilurzos ordered from Ziemann Holvrieka far more than just innovative brewhouse components. Rather, the order included a complete show brewhouse including all necessary tanks, malt handling, wort cooling and aeration, with a cast out wort volume of 88 hl per brew. The project was executed as a turnkey project, including the engineering, process technology and software, manufacture and procurement of the plant components, assembly and the final commissioning.

17 CCTs and 6 bright beer tanks delivered to California

In addition to the brewhouse technology, 17 cylindro-conical fermentation and storage tanks as well as six bright beer tanks were supplied for the new cold block. Each tank has a capacity for one, two or four brews. All tanks were built in Germany, insulated, shipped to California, installed at the construction site and equipped with a catwalk system.

With the commissioning of the new brewery in Windsor, the larger of the two brewery plants in Santa Rosa was put out of operation. However, the brewpub remains in operation, being for Natalie nothing less than the heart of Russian River and a real visitor magnet. In 2017, the taproom on Fourth Street had nearly 400,000 guests.

According to Natalie, it brewed around 30,000 hl in 2018. In 2019, it was around 40,000 or more hl. For comparison: In 2017, Russian River produced around 20,000 hl.

“We are making a big leap right now, but we want to maintain this level for a while and continue to grow only slowly,” said Natalie. “We are not planning to achieve the 70,000 hl really fast.”

The new brewhouse takes us to a completely different level

Of course, this capacity reserve is also evident in the brewhouse: The brewhouse is designed for eight brews a day. With an additional wort collecting vessel, even 10 brews would be possible. At the moment, Russian River produces a maximum of four brews in double-shift operation. The mere capacity was, however, never the key criterion for Vinnie. For him, quality always comes first. In this respect, the new brewhouse has long convinced him.

“The taste profile is less astringent, which I like much better. We have always produced really clean beer, but the new brewhouse takes us to a completely different level,” he said. Moreover, he likes to profit from an additional benefit: “The brewhouse is much more efficient, both in terms of malt yield and hop bitterness. Now, we need significantly less hops to achieve identical bitterness values.”

Even for those who are travelling to Sonoma County to taste Pliny the Younger, the new brewery offers good news — now 410 hl instead of the original 180 hl of triple India pale ale are brewed and served in twice as many locations — in the original brewery in the city center of Santa Rosa as well as in the new brewery in Windsor. However, the rules remain the same: Each visitor gets three hours of time or three glasses of Pliny, before having to give way to new visitors. After all, others also want to have a date with Pliny.

Hanspeter Geigle is a diploma brewmaster. He worked as a brewmaster in various breweries for ten years. He has been a project manager for 13 years. He joined Ziemann Holvrieka six years ago, where he realizes and processes projects all over the world.

Leave a Reply

You must be logged in to post a comment.