ZIEMANN HOLVRIEKA has been building innovative beverage equipment since 1852. Today, the Ludwigsburg, Germany-based company is making some of the most creative brewing equipment in the marketplace. In North America alone, the company has sold more than 800 fermentation tanks and is currently executing high-profile projects for craft heavyweights like Yards Brewery Co. in Philadelphia and Russian River Brewing Co. in Windsor.

But what’s really caught our collective eye about ZIEMANN HOLVRIEKA is the unique and innovative brewing processes the company has been releasing of late, and each technology is always awesomely named.

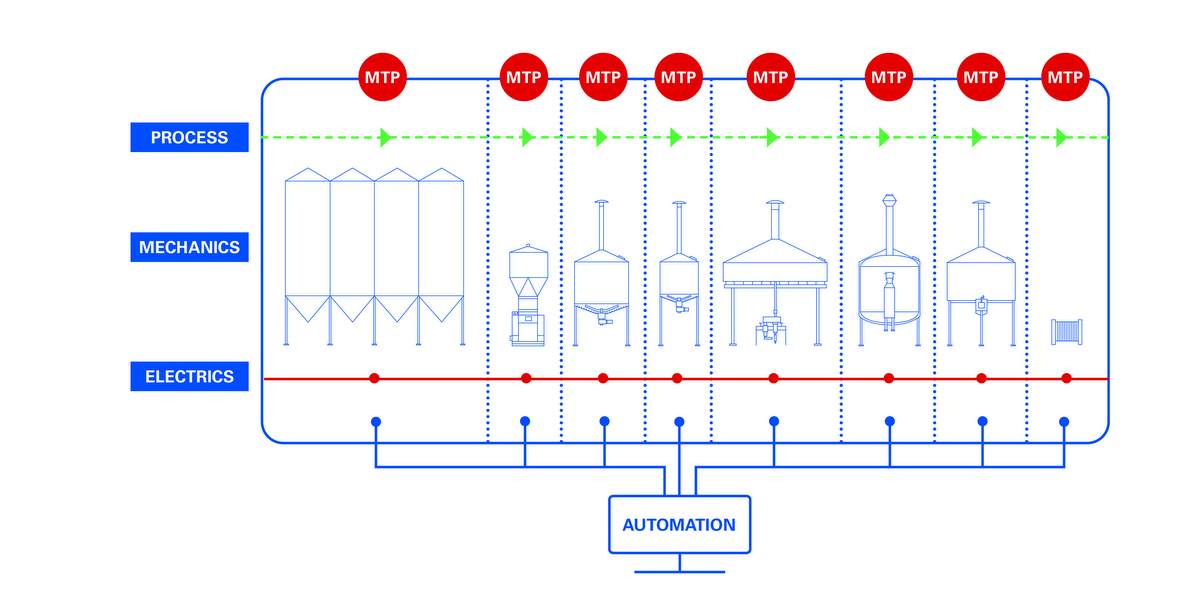

“Our hottest product is a brewhouse called Omnium by Ziemann,” said Udo Funk, sales director of ZIEMANN HOLVRIEKA in North America. “It’s designed to provide more flexibility regarding raw material and brew length, improving wort and beer quality with shorter process times. Omnium also requires less floor space. The centerpiece of the Omnium brewhouse is an innovative separation and extraction process called Nessie by Ziemann [which we’ve reported on before] that is nothing like a lauter tun or mash filter. The rotating sieves separate wort from spent grains in a continuous process. For craft brewers especially interested is the flexibility with respect to raw materials, 30° Plato or high amounts of wheat and rye are processed without problems.”

This gives the craft brewer better control of the wort composition and a much lower iodine value compared to the current state of the art brewhouse process. The resulting beer quality is superior with better stability and filterability. Overall, the combination of systems makes for a dream brewhouse. Another new development and part of the Omnium process is the fractional wort boiling: Janus by ZIEMANN. Part of the brew, instead of going to the wort kettle, is transferred to the Janus hop isomerization vessel. Besides significantly better hop yields, this process is especially suited for IPAs produced with high amounts of pellets. It dramatically reduces the whirlpool losses typically caused by the high hop pellet loads. The Omnium brewhouse also features Aladin by ZIEMANN for post-boiling saccharification of the wort.

The folks at ZIEMANN HOLVRIEKA share this brewing technology and knowledge all over the world. The first brewery to employ the Omnium is in Bavaria — called Schlossbrauerei Reckendorf.

“The decisive factor was flexibility,” noted Dominik Eichhorn, brewmaster and managing director at Schlossbrauerei Reckendorf. “In addition to the technological advantages, there are also various advantages regarding the building design. The Omnium brewhouse has reduced space requirements and requires lower costs for the foundations due to the Nessie design.”

You’ve been challenged

Now ZIEMANN HOLVRIEKA is looking for a similar partner in America to help experiment with this new equipment. Omnium is perfectly suitable to brew traditional Bavarian beers, but the ZIEMANN HOLVRIEKA team is looking to challenge the system a bit more. Udo and friends are currently looking for breweries who want to brew everything from big hoppy beers to session beers with a wide variety of raw materials — even beers that you wouldn’t be able to brew with a lauter tun or mash filter.

“For the next Omnium brewhouses, we are looking at capacities from 60 to 120 bbl per brew, designed for up to 16 brews per day,” said Funk. “If we all agree it might be a successful partnership we can offer the brewery test brews with Omnium in our fully equipped 10-hl pilot brewery in Germany.”

Funk is himself a beer tech wizard. He graduated from the Technical University of Munich (Weihenstephan) as a brewing engineer in 1994. Since then, he’s worked in the brewery supply industry with a focus on the process side, from malt handling to beer filtration. He has worked as a commissioning engineer, process engineer and project manager in Europe, Latin America and North America. In 2007, he moved to the United States to focus on the American market. Of late, he’s seen business slow for large craft brewers, but he also does expect healthy growth rates as these bigger breweries adapt to more challenging market conditions. For smaller production breweries, Funk still sees a lot of double-digit growth potential, mainly driven by customers who value local brews.

“This is the market segment where we as equipment suppliers see the best opportunities for new equipment in the next years,” said Funk. “Brewhouses starting at 50 bbl per batch, designed for 12 brews per day at 16 Plato. Those systems with a high degree of pre-fabrication with short installation times of approximately five weeks. Due to a more competitive market, we also expect more focus on equipment yields and expansion of existing facilities instead of complete new breweries.”

The 2018 brewing landscape has become ultra-competitive. The Brewers Association (BA) released its mid-year report and estimated that on top of the 6,600-plus breweries already in operation, 2,500 to 3,000 breweries are still currently in planning, based on active Alcohol and Tobacco Tax and Trade Bureau licenses. The BA also noted that 2018 is on pace to have the highest number of brewery openings and closings to date. With such a busy marketplace, what advice can ZIEMANN HOLVRIEKA share?

“As an equipment supplier, our recommendation for craft brewers is not to let your equipment restrict your creative brewing ideas,” suggested Funk. “Does your lautering system limit your choice of raw material? Do you have special requirements for hopping or dry hopping? Do you need to use the wort kettle for kettle souring? Find yourself an equipment supplier with engineers keen on developing innovative solutions. Think in long terms. Big goals are rarely achievable right away but might be easily implemented step by step. A successful brewery needs to balance production growth, operating costs and sustainability goals. At the same time the brewer always needs the flexibility to create outstanding beers that help the brewery to stand its ground in a highly competitive market.”

To learn more about ZIEMANN HOLVRIEKA and Omnium, Dominik Eichhorn, brewmaster and managing director of the Schlossbrauerei Reckendorf, will be attending the Brewing Summit in San Diego, August 12-15, speaking at various Omnium presentations. He will be available to answer your questions.

Leave a Reply

You must be logged in to post a comment.