Both large commercial and smaller craft beer breweries use sanitary pumps to transport viscous and non-viscous liquids during the beer-making process. Their important role in a brewery’s operation means careful attention to the selection is essential, and once put into operation, pumps must be well-maintained to sustain peak performance. Pumps can be divided into two basic categories: centrifugal and positive displacement. A centrifugal pump transfers centrifugal or kinetic energy into a liquid in the form of velocity and pressure. A positive displacement pump transfers a precisely measured amount of liquid from the inlet to the outlet for each rotation or stroke of the pump.

Centrifugal pumps

In a brewery, the sanitary centrifugal pump is the most commonly used pump and includes several types: multi-stage, open impeller, liquid ring and submersible. A centrifugal pump is ideal for transferring non-viscous liquids (little or no solids content) at a high volume and a relatively low pressure (less than 100 psi).

Positive displacement pumps

The most commonly used positive displacement (PD) pumps in the brewing industry are the positive rotary, the flexible impeller, the progressive cavity and the air-operated diaphragm pump. A PD pump is best used to transfer a thick liquid or one with a high concentration of solids, such as mash-in-wort, liquid sugar, syrups or yeast slurry.

The pump performance curve

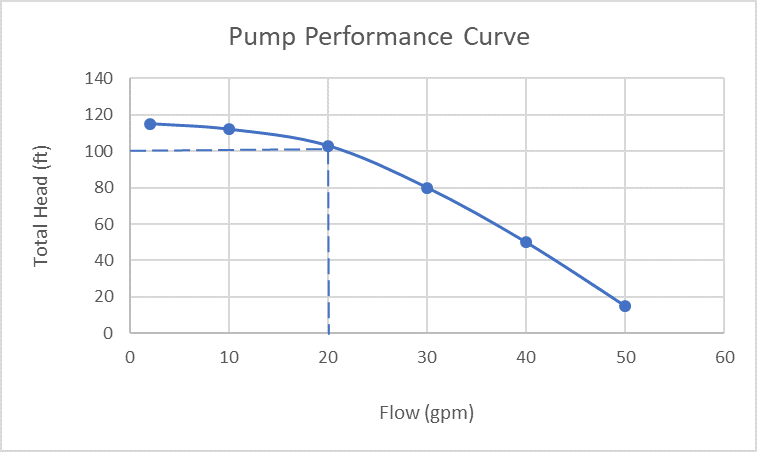

While there are several methods used to select a brewery system pump, the most common technique uses a pump curve. A pump curve represents data showing the discharge pressure (head) created by the pump at a selected flow rate. Head, expressed in units of height, such as meters or feet, is the maximum height the pump can deliver.

The simple pump performance curve shown in Figure 1 demonstrates the tradeoff between pressure head and flow rate. Higher flow rates mean lower outlet pressures. For this pump, if the desired flow rate is 20 gallons per minute, it will deliver 100 feet of head. Every pump manufacturer publishes a pump performance curve for each pump model.

How to select a centrifugal pump

The actual flow rate achieved by a centrifugal pump will depend on the physical layout of the system, pipe friction as a function of length and pipe diameter, the elevation difference between the fluid source and destination, and the fluid viscosity. The selection process must also consider the net positive suction head available (NPSHa) and the power required to drive the pump. A positive displacement pump will produce its rated flow for any physical environment.

Pump size selection

Determine the flow rate

To size and select a centrifugal pump, first determine the flow rate. Pipe diameter is a significant factor in determining the flow rate for the brewery process. Most fluid transfer operations are best performed within a range of recommended fluid velocities to achieve nonturbulent flow and minimize friction pressure loss. Other fluid transfer systems are less sensitive to flow conditions. To prevent turbulence inside pipes, laminar flow must be maintained by keeping flow rates below a critical velocity. The maximum velocity is a function of pipe size, fluid density and fluid viscosity.

An application where turbulent flow is desirable is Clean-In-Place (CIP). In a brewery, CIP is a technique for cleaning the pipe interior surfaces, vessels and tanks without disassembly. Turbulence improves the scrubbing action of the CIP fluid inside pipes.

Determine the total head

The Static Head is the height difference between the fluid surface in the suction tank and the fluid surface in the discharge tank (discharge pipe end). The friction head depends on the flow rate, the pipe size and length, along with the liquid viscosity. This is calculated from the values listed in the tables for water and viscous liquids found in “Cameron Hydraulic Data,” Ingersoll-Rand. The total differential head is the pressure that the pump must generate to deliver the required flow rate and is the sum of the static head (positive or negative) and the friction head.

Net positive suction head available

The net positive suction head available (NPSHa) is the difference between the pump suction absolute pressure (inlet) and the liquid vapor pressure at the pumping temperature. For proper pump operation, the pressure at the NPSHa must exceed the vapor pressure to maintain the liquid phase. Cavitation occurs when the vapor pressure exceeds the pressure at the pump suction, and vapor bubbles form in the liquid. The result is a loss of pump efficiency and possible pump damage. Pump manufacturers supply the net positive suction head required (NPSHr) for each pump.

The net positive suction head available (NPSHa) is the difference between the pump suction absolute pressure (inlet) and the liquid vapor pressure at the pumping temperature. For proper pump operation, the pressure at the NPSHa must exceed the vapor pressure to maintain the liquid phase. Cavitation occurs when the vapor pressure exceeds the pressure at the pump suction, and vapor bubbles form in the liquid. The result is a loss of pump efficiency and possible pump damage. Pump manufacturers supply the net positive suction head required (NPSHr) for each pump.

Pump power

The pump driver, usually an electric motor, diesel engines or steam turbine, is sized by determining the power required: Pump power = flow rate x total differential head x liquid density x acceleration due to gravity ÷ pump efficiency.

Select a pump

The pump can be selected based on the pump manufacturer’s catalog information using the total head and flow required, NPSHr, the pump power needed and the pump type suitability to the application.

Pump maintenance

Pumps are a critical piece of equipment for a brewery process. When a pump shuts down, so does the entire operation. A pump maintenance plan should be implemented, including regular checks to keep the pump in optimal condition.

Daily inspections

Daily pump inspections should be made, and any irregularities should be recorded, including changes in the pump sound, sudden changes in bearing temperatures and seal chamber leakage. Pressure gauge readings, flow meter monitoring and vibration observations should be part of the daily check.

For pumps with attached recording instruments that monitor current capacity, pressure and power consumption, trending charts should be created to permit the observation of changes as a function of time. Observed trends, indicating a deterioration of specific performance values, can be identified and the appropriate maintenance task scheduled.

Leaks

Look for new or excessive leaks, especially dripping oil from gaskets. Inspect the pump casing, seal chamber and piping.

Noises

Listen carefully for any unusual or disturbing sounds. If some cavitation and bearing noise is present, make sure it is not any louder than normal. Lubricate the bearings.

Temperatures, heating and cooling

The pump temperature should be monitored every day to ensure the pump is running at the optimal temperature. The type of fluid will determine the ideal temperature. However, it should not fluctuate excessively from day-to-day.

Oil

Examine the oil and the oil levels on a regular basis. If it is watery or has an odd color, it should be changed.

Pump performance parameters

Monitor the discharge and suction pressure for extreme movement in either direction. Check the pump’s power, flow rate, speed and efficiency. By tracking these indicators, a potential problem may be identified early enough to prevent pump damage and to avoid costly downtime. Quarterly procedures should include the following tasks:

- Change the oil.

- Inspect the pump shaft alignment and realign as required.

- If the pump has been idle, check the mechanical seal and replace as required.

- Make sure the foundation and hold-down bolts are tight.

Annual inspections, check these three parameters:

- Pump capacity

- Pump pressure

- Pump power

If the pump performance is not satisfactory, disassemble the pump, inspect it and replace the worn parts.

Final thoughts

Adherence to strict guidelines for the selection and maintenance of pumps will help breweries achieve their product objectives, guaranteeing that the next tall cold glass of beer you drink will be an exceptionally favorable and enjoyable draft.

David Holland is the vice president of Mahan’s Thermal Products. Holland has a degree in mechanical engineering which has helped him acquire an extensive background in general contracting and mechanical contracting. He also has extensive experience in the design and construction of mechanical systems and controls. He is also a factory certified as an authorized service provider for Alfa Laval, including designing, repairing and re-rating plate and frame heat exchangers and pumps.

Leave a Reply

You must be logged in to post a comment.