Briess Malt and Ingredients Co. continues to invest heavily in its Manitowoc, Wis., footprint. America’s most famous maltsters acquired a large grain processing operation in Manitowoc back in 2014 — about 40 miles from its Chilton campus in Wisconsin. The site was selected as the company’s eighth roaster after more than a year of study and discussion. The expansive Manitowoc operation includes a 244 ft elevator, onsite lab, 4.3 million bushels of storage along the shore of Lake Michigan and rail connection to the company’s Ralston Elevator in Wyoming and two other malting operations in Wisconsin.

In 2015, Briess recommissioned a large malthouse on that Manitowoc property, more than doubling malting capacity. In 2017, the company announced a $17 million expansion of its barley processing and malting facility, including replacing an aging structure and installing a roaster and automated packaging line for the production and packaging of specialty roasted malts. This week Briess announced even more investments in Manitowoc, commissioning additional malthouses and building the Briess Experience Center, a gathering spot to engage with customers and highlight the company’s rich culture.

“The Briess Experience Center will be a space where our customers, partners and employees can interact and learn,” explained Ryan O’Toole, president and COO. “It will be an environment that will stimulate the sharing of knowledge, the development and application of products and the strengthening of great relationships. The Experience Center will house components of our development and application equipment, a training and knowledge sharing classroom and a social engagement area. The history and journey of Briess through 143 years of malting and ingredient production will be woven into the fabric and visual displays throughout the space. We wish to share the knowledge of our craft, our culture and our longstanding Briess traditions with our customers and team at this site. We look forward to sharing this experience in the next 24 months.”

As a result of Briess’ overall investment in Manitowoc (especially that recent $17 million expansion), the company has also announced its Chilton Malthouse will be decommissioned in probably a span of one to three years. According to the press release: “Briess assessed its current malting facilities and determined the prudent direction would be to increase production at the Manitowoc Malthouses. This decision will also make our supply chain more efficient and eco-friendly.”

Briess is still committed to the City of Chilton. Its headquarters and other manufacturing sites will remain there, and the company has offered job opportunities to all its Chilton Malthouse staff, but that facility has a lot of rich history that will certainly be missed.

“The Chilton Malthouse has been malting grains for over a century,” said O’Toole. “The relationship with the malthouse started many decades past by Eric Briess, the third generation to operate the Briess family business. The Chilton Malthouse was a monument to specialty malt innovation in the United States. The building housed many of the first pieces of equipment dedicated to the art of specialty malts and craft malting. It was the vision of Roger Briess to be the provider of superior specialty malts to homebrewers and to the fledgling craft brewing community in the late ‘70s, ‘80s and ‘90s. And with that, Roger Briess invested in and used the Chilton Malthouse to support his customers’ needs.”

The Chilton Malthouse is the smallest of Briess’ three malthouses. It is actually a small-scale production facility that currently produces handcrafted specialty malts for craft beer. So, where will that craft beer-focused malt production go?

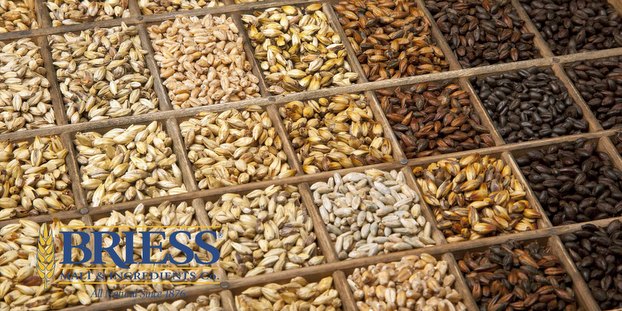

“That tradition of malting and providing specialty malts will continue in the Manitowoc facility in the same manner as it has in Chilton,” said O’Toole. “The improvements being made at our Manitowoc site will ensure we stay true to the Briess family malting legacy. We will carry on the practice of carefully selecting, malting and roasting our grains to exceed our customers’ expectations.”

Built in 1901, the Chilton Malthouse blends the historic charm of the original wooden structure with modern specialty malting techniques and equipment. The facility features include rail service to Manitowoc, roasters and an automated packaging line and lab. It is a Kosher and USDA organic certified facility as well. Briess noted that after it dismantles the building, it will save key pieces of history to showcase in its Briess Experience Center.

We’ll keep you updated on all these plans, but while you wait, here’s a timeline provided by Briess on the Chilton Malthouse’s legacy.

Chilton Malthouse Timeline

1900

A group of local businessmen scrape together $100 and start The Chilton Malting Company to provide local farmers with an outlet for selling their barley, provide local employment and generally benefit their small, agricultural community.

1901

Groundwork for the elevator and malthouse began. It cost $150,000 to build and was operating by the end of the year. It took 66 carloads of stone and four weeks to build the foundation. Over six weeks, carpenters and masons used 1,145,000 bricks and 1,045,000 feet of lumber to construct the operation.

1919-1933

The Chilton Malting Company survives Probition in part by adding coal to its product mix and offering free coal shovels with a customer’s next order during part of this time.

1950s

Third generation maltster Eric Briess forms a relationship with the Chilton Malting Company to supply the Briess family malt export business with malt for customers. He has K-Ball Roasters from the G.W. Barth Company of Germany installed for the production of roasted caramel malt.

1960s

More K-Ball Roasters are added, bringing to four the number in operation in the malthouse. Equipment and process upgrades during the 1960s triple export and domestic shipments.

1971

Fourth generation Roger Briess continues the family malting tradition after Eric Briess passes away. Trained at the famed Weihenstephan University in Germany, Roger recognizes the potential of the young American Craft Beer movement and installs additional roasters in the malthouse to expand capacity and capability.

1978

The Briess family acquires Chilton Malting Company, which becomes Briess Malting Company. Roger Briess dedicates resources of the family malting business to the production of domestic production of specialty malts for American Craft Beer.

1990s

Additional roasters are added, sending the aging and inefficient K-Balls into retirement.

Today

The Chilton Malthouse is marking its 118th year of continuous operation.

Leave a Reply

You must be logged in to post a comment.