This hop logistics feature was sent our way by the team at Intel.

It takes two hours and four minutes for fresh hops to make the 77.5-mile journey from Rogue Farms to its brewery in Newport, Oregon. Three smart sensors that ride along in every shipment bound for Rogue’s production facility enable the company to precisely track everything from temperature and humidity levels to location status and estimated time of arrival.

Freshly harvested hops have a short shelf life, which means they need to be used before going bad. Ensuring the freshness of hops used by Rogue Ales and Spirits is mission-critical because they are used for wet-hop brewing. Rogue is using Intel technology to make sure its hops make it from field to brewery at the peak of their freshness. For the Oregon-based craft brewing company, streamlined delivery of fresh hops means better tasting beer. That translates into more satisfied customers and, ultimately, increased revenue.

Connected logistics

Safeguarding the freshness of perishable products is one of the primary benefits of Intel’s Connected Logistics Platform, which uses smart sensors to monitor key environmental variables. An estimated 30 percent of all perishable products spoil before they complete the journey from farm to table. But now, shippers can check-on the health of their cargo at any step in the process, such as on board a trailer or in a warehouse. Companies like Rogue, who ship large quantities of perishable products, can now control storage conditions, as well as track shipments, in real-time.

Remember when we journeyed to Rogue Farms for the hop harvest?

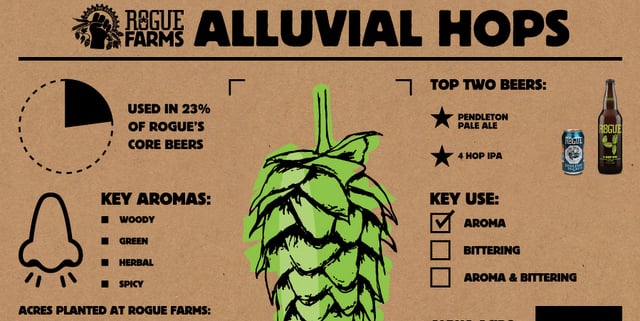

Thanks to the Internet of Things (IoT), Rogue can track the 10 varieties of hops it grows from the time they are harvested until the moment they are used by the brewmaster. Shipments of hops are monitored using what Intel calls a “visibility platform,” which monitors and reports on the condition and location of each shipment.

Rogue’s brewery receives a location status alert every 10 minutes, and when the shipment reaches the halfway point, the brewing process begins. Once the hops arrive, they are immediately unloaded and moved directly into production. Thanks to those status updates, the brewing team can time its process to coincide with the delivery. Not only does in-transit monitoring reduce spoilage, it increases overall production efficiency.

Integrated supply chain solution

Intel’s supply chain solution can be customized for monitoring shipment-critical variables and can easily be integrated with climate control and freight-tracking technology. Moreover, it can be used to help analyze and optimize a company’s entire supply chain efficiency. This can, for example, help a shipper of perishable products determine if a recurring problem with spoilage is the result of an in-transit issue, a warehouse storage problem or some other factor.

Just as Rogue proactively monitors shipments of hops, other producers can use connected logistics to reduce waste. By analyzing all their relevant supply chain data, shippers can assess the quickest and most cost-effective way to transport perishable products from point A to point B. Integration with the IoT further enables the analysis of real-time shipping data for adjusting factors ranging from refrigeration temperature to preferred shipping route.

Connected logistics technology from Intel powers a fully integrated supply chain solution that provides shippers with a granular view of shipments at the pallet, package and even item level. Monitoring solutions can be customized by suppliers and shippers in order to meet the needs of any business use case.

Edge intelligence and interoperability

Shippers like Rogue also benefit from edge intelligence enabled by Intel quad core Atom processors that are at the heart of the connected logistics platform. Offline data processing facilitates real-time analytics, without the need for Cloud connectivity. Processing data on the edge can be an economic alternative to cloud-based solutions.

Intel’s connected logistics solution is also designed for interoperability, which gives small businesses like Rogue access to the best available technology solutions. In fact, Intel was one of the founders of the Open Connectivity Foundation, which has helped develop interoperability guidelines and certification programs for IoT devices. Open standards streamline integration between devices and vendors.

Security is another important priority for enterprise-scale shippers. Intel’s technology provides end-to-end security at the hardware level, all the way down to the silicon, in addition to best-in-class software security solutions.

Beyond perishables

Connected technology is helping to reduce waste and improve efficiency for Rogue and other companies that ship perishable products. In addition to safeguarding perishable shipments, Intel’s connected freight solution has immediate applications for pharmaceuticals, high value goods and capital equipment.

Now, shippers can tap the power of the IoT in order to cost-effectively track and monitor their shipments throughout the supply chain. Edge intelligence and data granularity facilitate business insights that can be translated into immediate action. For Rogue, Intel is the secret ingredient for great-tasting beer. For companies in other industries, Intel’s connected logistics platform promises to minimize waste, reduce costs and increase revenue.

Leave a Reply

You must be logged in to post a comment.