This has been a super dumb, no-good year, and some breweries have used the slowdown to tinker. Greeley, Colo.’s WeldWerks Brewing, for example, has spent the majority of 2020 working on improvements across the brewery, such as beer trials, new equipment and revamped artwork to put it in better position to thrive when life and business returns to normal.

Putting beers on trial. This past year, the brewery conducted small trial runs to improve the quality of their sours, stouts and even Juicy Bits, the brewery’s wildly popular flagship Hazy IPA. For the latter, WeldWerks looked at tweaks to the whirlpool hop schedule, salt, bittering hop, dry hop rate, malt, attenuation, as well as enzyme experiments, to get the product just right.

“Results from these small trials can be fed into other beers and styles, implemented on a larger scale—eventually permanently,” says Arne Garlick, Director of Brewing Operations at WeldWerks. “It is a slow and somewhat arduous process overall, but ultimately results in a gradual evolution to make sure that our beer stays relevant to consumer palates in an ever-changing landscape.”

To dial in on their efficiency and quality, WeldWerks invested in a centrifuge from GEA and a pasteurizer from Goodnature. The centrifuge separates the beer from the solids, allowing for the hop-loving brewery to capture more beer that would have otherwise been dumped due to sediment and yeast buildup; the clarification process results in an 15% increase in packaged beer. With the pasteurizer, eliminating infections in their barrel aged beers and creating shelf-stable products, particularly for their Froot Camp smoothie sour series, were two of the biggest reasons to bring in this equipment.

“When you’re working with unfermented fruits and sugars, you run the risk of cans having refermentation occurring in package which can lead to exploding cans,” says Skip Schwartz, Innovation and Wood Cellar Lead. “Not only does the pasteurizer help us package our smoothie beers safely but it also gives us an opportunity to expand the ingredients that we can use in our barrel aged stouts, such as raw coconut and real Mexican hot chocolate powder, a key ingredient in our Medianoche de los Muertos.”

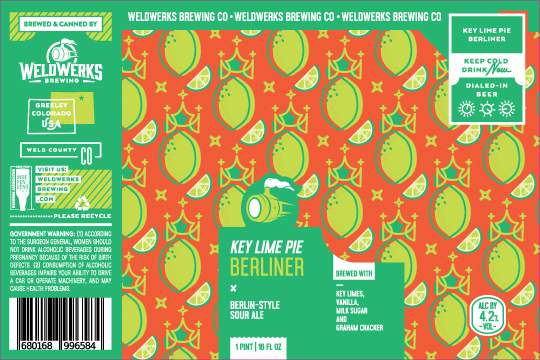

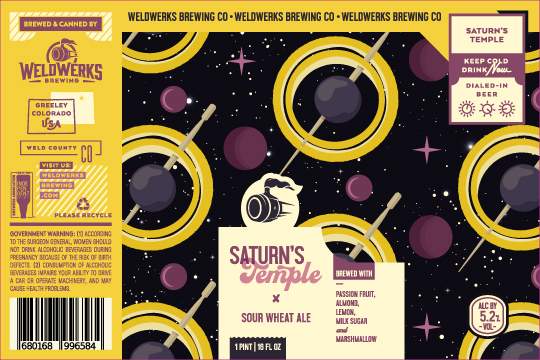

Brand quality check. The WeldWerks brand has evolved over distinct phases, from early bootstrap years and a brand refresh in 2017, to establishing a consistent brand identity. The brewery has worked tirelessly throughout the years to create a stable vision for its creative imagery; the label artwork process is yet another feather in the brewery’s cap. WeldWerks looked to Rachel Nedrud of Freeline Creative for the design refresh, focusing on a larger canvas for engaging imagery and Nedrud’s eye for watercolor work.

“To help create a more dynamic on-shelf presence, we ‘opened up’ the label template a bit more to allow for a greater proportion of the design to be visible at all times while moving towards more kinetic, eye-catching pattern-work for the enlarged backgrounds,” says Jake Goodman, WeldWerks Director of Marketing. “We are massively in love with the new direction and we’re excited to see where it goes.”

As WeldWerks navigates what has been a tumultuous year for the brewing industry and beyond, the brewery is forging ahead in 2021 with a brand new mural, building upgrades such as office space and an expanded barrel room and updated signage.

Leave a Reply

You must be logged in to post a comment.