Over the last decade, the rise of craft brands has changed food and beverage preferences across the world as a new kind of consumer is demanding consistently high-quality products that deliver unique and interesting flavor profiles. This rise of craft brands has now brought about the rise of the machines.

Over the last decade, the rise of craft brands has changed food and beverage preferences across the world as a new kind of consumer is demanding consistently high-quality products that deliver unique and interesting flavor profiles. This rise of craft brands has now brought about the rise of the machines.

To address the challenge that traditional manufacturing processes pose for delivering consistency, Analytical Flavor Systems has created Gastrograph, the world’s first artificial intelligence and machine learning process control solution for the food and beverage industry.

“Food and beverage CPGs produce inconsistent products largely because they don’t have as much control over the process as they’d like,” said Jason Cohen, founder and CEO of Analytical Flavor Systems. “This is particularly evident in producers’ inability to manage the effects of raw ingredient deviations and degradation, as well as flaws that occur throughout the manufacturing process that adversely affect the product’s flavor-profile. This lack of control can significantly hurt the brand and product sales because consumers demand a consistent experience every time they buy that product.”

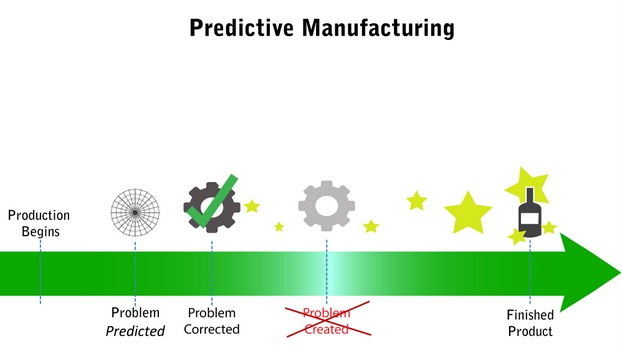

Gastrograph uses modern techniques that have recently become available, like machine learning and artificial intelligence. This new technology provides predictions for flavor profile formation and optimization, allowing early detection and correction of batch-to-batch deviations, flaws, taints and contaminations at any stage of the production process, from raw ingredients to the finished product. The intelligent software learns to control the manufacturing process, updating times, temperature and ingredient additions automatically — ensuring the finished product hits the target flavor profile every time.

“We watched small and large producers alike struggle to work with existing process control solutions from SAP and Microsoft Dynamics,” Cohen added. “We realized that no one had ever built a MRP [Material Requirement Planning] or LIMS [Laboratory Information Management Systems] to address the challenge that the food and beverage industry faces. As a result, no one had ever taken the massive amounts of data that are entered and stored in these systems to determine how to make their production more efficient in order to allow for greater consistency and higher quality while creating optimized flavor profiles that meet consumer demand. We’re really excited to be the first to introduce this technology to the industry.”

Here is what Yards Brewery Director of Quality Assurance Franklin Winslow had to say about it:

“Gastrograph has become a key tool for understanding how subtle changes in the flavor of our beer will be perceived by our drinkers. The system allows us to track subtle changes easily, while giving us a better sense of product variation. Gastrograph has revealed details about our beer we never knew before, and this insight has allowed us to make more informed business decisions with minimal time investment and, most importantly, increased the consistency of our beer.”

So, you won’t like this part, but AB InBev, the world’s largest beer producer and a leading innovator in flavor science and quality control, has invested heavily in Analytical Flavor Systems to ensure it has the resources to optimize the flavor and process across their expansive portfolio.

Columbus Brew Adventures liked this on Facebook.

RT @CraftBrewingBiz: Analytical Flavor Systems predictive brewing software. https://t.co/4gfJaLx2K8 @Gastrograph

RT @CraftBrewingBiz: Analytical Flavor Systems predictive brewing equipment. https://t.co/4gfJaLx2K8 @Gastrograph

RT @CraftBrewingBiz: Analytical Flavor Systems predictive brewing equipment. https://t.co/4gfJaLx2K8 @Gastrograph

RT @CraftBrewingBiz: Analytical Flavor Systems predictive brewing equipment. https://t.co/4gfJaLx2K8 @Gastrograph